Why isn’t there a fire rating standard for cable management systems?

It is well-known that once a British standard is introduced there becomes a better understanding of best practice. As an example, BS 8539:2012 for post-installed concrete and masonry anchors came in to reduce the amount of fixing failures on-site. The standard outlines the responsibility of each stakeholder to ensure the correct fixings are specified, supplied, installed, and tested and today there is an increasing awareness around anchor compliance.

The topic of fire testing and regulation has been bought into sharper focus since the devastation of Grenfell. It is an issue that both the government and the industry are trying to resolve. One of the growing concerns within the industry is that there is not a harmonised British standard to determine the ‘fire rating’ of cable management solutions. This problem is made worse by the misuse and misunderstanding of the term ‘fire rating’.

Buyers regularly ask, ‘what is the fire rating of this product’, and in many cases, the supplier will refer back to the ‘BS 476 fire curve’, but this is not designed for cable, support or bracketry solutions.

In our latest podcast, Stevan Grkinic sits down with Tim Brown to explore the subject of ‘fire rating’ and discuss why the current standards are not a reliable performance indicator for cable management systems.

The podcast answers the following questions:

- What does the term ‘fire rating’ mean?

- Why the German standard DIN 4102-12 is not a suitable standard for testing cable basket.

- Why BS 476 fire curve is not a reliable indicator for the performance of cable management systems

- Why should the industry understand the meaning of a ‘fire rated’ product?

- How can an M&E contractor follow best practice?

“There is no point having a fire-rated product that after 120 minutes has the load-bearing capacity of a leaf” (Tim Brown, 2020)

What does the term ‘fire rating’ mean?

The term ‘fire rating’ is a classification system, often relating to the BS 476 fire curve, that provides a classification of the fire resistance of a product, usually a building material, after undergoing fire tesing. However, there is not a harmonised standard for fire rating that can be attributed to cable management or suspension or support systems. On that basis, there is no consistent testing method for cable management systems of support bracketry. A standard fire test involves placing a product into a furnace for a certain amount of time at a certain temperature. Once the test has been carried out, the manufacturer can state that a product can withstand a temperature for a certain amount of time. However, manufacturers and suppliers are unable to confirm the impact that the fire test has had on a product's performance.

Why is the German standard DIN 4102-12 not a suitable test standard for cable management systems?

DIN 4102-12 is a German cable test standard, which is not a standard that can be used for cable management systems. Simply because the standard applies to just the cable and not any of the associated products that come with a cable management system (for example the cable basket).

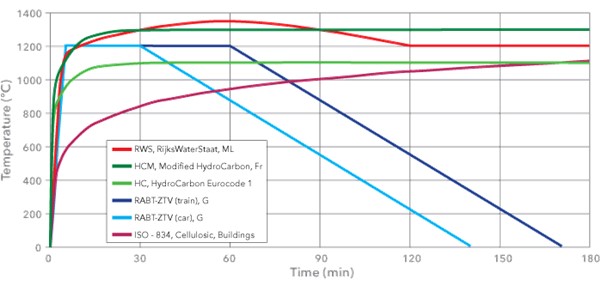

BS 476 fire curve example

Why isn't BS 476 fire curve a reliable indicator for the performance of cable management systems?

The BS 746 fire curve simply declares that a product can withstand a temperature for a certain amount of time. It is primarily a standard used for fire testing building products. In many cases, both the manufacturer and suppliers will infer that because a cable has been fire tested, then the cable basket (cable management system) has a fire rating. This is factually incorrect. There is no harmonised standard for testing a cable management system that can determine the ‘fire rating’ of the cable basket.

When specifying a cable management system, the buyer should ask the supplier several questions:

- Has the fire test been carried out by a third party?

- Is the test based on an ambient temperature or based on the performance of the product at the end of the test?

- How is the load performance of a cable management system after the fire test.

Why is terminology within fire rating important?

In a fragmented industry often dominated by product language going back generations, industry terms are regularly misunderstood and misinterpreted.

For instance, it is common for M&E contractors to assume that if a cable has undergone fire testing, then a cable management system has achieved a fire rating. However, without a harmonised fire rating standard for a cable management system, a manufacturer is unable to provide a fire rating. Removing the confusion around the terminology provides confidence within the supply chain.

In the most severe cases, if the terminology is used incorrectly it can be very dangerous. If a manufacturer has sold a product based upon a product being ‘fire rated’, and that product fails, then unless the manufacturer can show test evidence then they can become liable.

Can we provide fire rating data for other fixings?

Yes, for instance for all ETA-approved anchors, fire performance data can be verified. The fire rating will be shown through the ETA certificate. However, what is not often taken into consideration is that, regardless of the fire testing data, it will not provide information on the load-bearing performance of the anchor in those temperatures.

What is happening within the industry to harmonise a fire rating standard for cable management systems?

There are several key organisations within the industry that are trying to create a standard. For example, take BEMA, they have a separate cable management committee that has been monitoring this issue for a few years.

According to Tim, the committee is in the process of creating a standard. Traditionally standards take a long time to create, as it requires full cooperation between all relevant stakeholders. Once the standard is created, the supply chain must educate and raise awareness around the standard, otherwise, the industry may not adhere to the new standard.

How can an M&E contractor follow best practices?

In most cases, mechanical and electrical installations are usually left to the last minute, faced with tight deadlines, products are often selected and installed without due diligence. We recommend early and continued engagement with relevant stakeholders to reduce the risk of the incorrect product arriving on-site.

When a contractor is asked:

What is the fire rating of the product?

The first route a contractor should take is to speak to the manufacturer’s technical department and ask the following questions:

- What tests have been carried out?

- Have those tests been carried out by a third party?

- Can you provide test results?

- Can you provide performance data after testing?

To conclude, as the industry is becoming increasingly litigious, there is a clear need to create one harmonised standard for fire rating of cable management systems. In the near future, with the introduction of the ‘Golden Thread’ legislation, it will be down to the duty holders to hold health and safety and fire risk awareness product data on all products used on-site.