If you’re thinking of working at MIDFIX, you might wonder what makes us the right partner for you; and understandably so.

Why should you choose to work with us? Do our beliefs align with yours? What clients are we a good fit for?

These are all valid questions that will help you determine whether or not we are compatible to work together, and we’re happy to help answer them.

- How do we define MIDFIX’s core customer?

- What does MIDFIX believe and where are we headed?

- Why do we believe change is necessary for the marketplace?

- What do we believe has inspired this change?

- Why do we believe it is the right thing to do?

- Who are we not a good fit for?

Often, even when something sounds great in theory, it just doesn’t feel right. If by the end of the article, you still want to work with us, then there’s your answer! We’re honoured that you’re considering working with MIDFIX.

How do we define MIDFIX’s core customer?

In order to gauge who is typically the right partner for us, you should know our core customer. This may seem obvious, but we typically work with contractors in the mechanical and electrical (M&E) sector of the construction industry.

Ideally, we love to work with people who genuinely have best practice in mind. If you are wholeheartedly bothered about compliance, then you are the perfect fit for us.

Typically, compliance is just a box to tick for contractors. While that’s better than nothing, if you’re actively trying to make a difference in our industry, then that shows how much you care and share our vision, so all the better! You’d be joining us as we go down this road towards a safer future.

What does MIDFIX believe and where are we headed?

Here at MIDFIX, we want to make best practice second nature; that’s our ultimate goal.

We believe that change is inevitable in the M&E sector because certain practices are just not sustainable anymore. We have to start progressing by adapting to more modern and optimised practices.

We also believe that safety should always be the #1 priority and that it should never be compromised for cost. This is quite contradictory to current popular practices because the price is usually the leading motivator. In the world we live in, of course the price matters! It’s completely reasonable to be concerned about cost. Except, it shouldn’t supersede safety, and that’s the key point.

Working in M&E and building services means that our products and services play a part in safety-critical installations and therefore have the potential to cause physical harm (or worse, loss of life) if something goes wrong.

With that level of responsibility, we feel that it’s our obligation to promote and ensure safety as much as possible, which means best practice, training, and evidence to back up our work.

But with the way the business is today, this is easier said than done. However, it is bound to change, albeit slowly (but surely!).

Why do we believe change is necessary for the marketplace?

Considering how many lives have been lost or impacted due to failures and poor practice, we should always be conscious about safety in our industry.

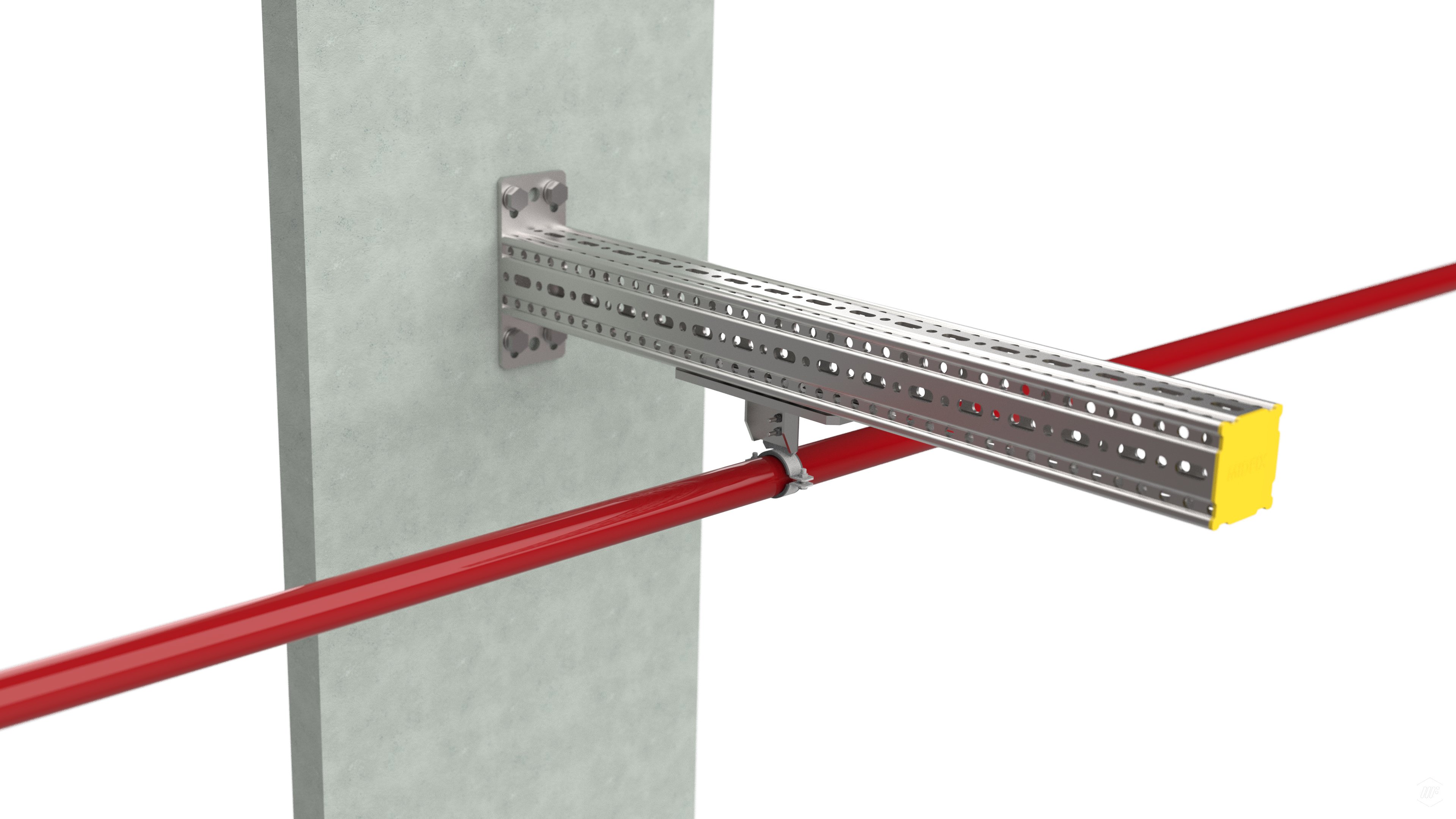

Supports are a key element in every building services installation, and crucial to the integrity of the systems they support and the building occupants’ safety. Therefore, the attention to detail they require should never be underestimated.

Mixing and matching untraceable components of unproven performance from various sources is a common practice in M&E. This is usually an honest mistake due to blameless ignorance, as people might assume the data behind the individual products is sufficient, so to the best of their knowledge, they think they’re being compliant.

However, it’s a flawed approach because despite the components being tested separately, there is nothing that indicates the products work well together as a system, therefore the ‘data’ is null and void. Using the manufacturer's data alone as ‘evidence’ is not sufficient enough to prove that your brackets are fit-for-purpose.

Likewise, deliberately choosing over-sized and over-specified materials, AKA ‘over-engineering’, in an attempt to ensure lack of failure is also not considered evidence. Remember, failure isn’t the issue at hand; it’s a lack of evidence. If you reflect about it, probably little to none of your brackets have actually failed, but at the same time, they most likely can’t be backed up either.

To add, cost seems to be a leading motivating factor, and while this isn’t exclusive to construction, it’s a prevalent issue in our industry. Quite often contractors will specify one product over the other simply because it’s the cheapest option, regardless of quality, compliance or suitability.

While cost will always be a factor whether we like it or not, it should not be the priority by any means. Moving from a cost-based approach to an evidence-based approach would solve many safety-related issues in construction.

What do we believe has inspired this change?

As more effort is being made to reduce risk and raise standards within the industry, it is becoming increasingly more common that contractors are required to provide design verification for loads of the supports.

This means that engineers need to have dependable information and load data for the components and connections, and evidence that the products specified by the engineer are the same ones that end up being used.

This movement is largely thanks to the introduction of regulations, recommendations, and guidance documents such as the 2018 report by Dame Judith Hackitt titled ‘Building A Safer Future’, which came about following the Grenfell Tower fire.

A notable quote from this quote is ‘Principal contractors and clients should devise contracts that specifically state that safety requirements must not be compromised for cost reduction’.

Another example is the BESA TR50 ‘Guide to Good Practice’. While the former was specific to high-rise buildings, and the latter to supports and fixings, their principles pertain to most construction areas.

Reports like these have led to industry practices being scrutinized under the microscope and longstanding outdated practices being re-evaluated. Now, more people are having to demonstrate how they contribute to ensuring the finished building meets the required standards for the ongoing safety of it and its occupants.

Why do we believe it is the right thing to do?

You may ask yourself, what’s the incentive? Well, apart from the clear foremost advantage of better safety, and peace of mind (of all parties) that the structure is fit-for-purpose, those that embrace this best practice approach will ultimately gain a competitive advantage.

They will become more attractive to their clients in the long run and be at the forefront of the industry as early adopters of changing practices for the better.

Think about it. Who in their right mind would willingly choose not to do a job as correctly and safely as possible? The better question is, why wouldn’t you?

Plus, it will further encourage the importance of choosing safety over cost and prompt more people to join the movement towards a more compliant and conscious industry.

Who are we not a good fit for?

Anybody who is procuring solely based on cost is not a good fit. If your mentality with every requisition that comes in is to compare with others and choose the cheapest option, it probably means you aren’t interested in what’s involved in the quotation (i.e. why is it more expensive? Is it because it’s higher quality, more compliant, better suited, etc.?). Or anything besides cost, for that matter, and that’s not what we stand for. The long-term value of best practice might not be your highest priority.

There’s a reason why certain options may be cheaper than others – that can’t be the only thing you take into consideration. What about quality? Innovation? Safety-compliance? Suitability to the application? These are all factors that should be considered along with the price.

Moreover, often these decisions are made based purely on the initial cost of a product. They don’t take into account that more money may be spent later on, to make up for the things that made the product cheaper, to begin with e.g. costly rework. So really, you wouldn’t be saving much at all, if anything.

It’s might seem like a good idea to buy the individual products at the ‘best’ possible price to do the required job, but if it takes you three times longer to fit it or it causes a failure, etc. then the final costs could be much higher.

We understand that this cost is the primary consideration for some contractors and transaction-oriented businesses, and that’s fair enough. But needless to say, in cases where decisions are made hastily with price alone in mind, those contractors might not be the most compatible partner for MIDFIX. Cost-cutting doesn’t go hand in hand with compliance, nor with our mission statement.

On the other hand, those that embrace the long-term value of best practice are definitely in line with our values.

Conclusion

We hope this article has allowed you to ask yourself what you care about. Are you more concerned about A, the bigger picture with regards to leading the M&E sector towards safety and compliance, in turn making the world a safer place for everyone? Or are you mainly interested in B, keeping costs to a minimum, regardless of the outcome?

If you answered with A, then you’ve come to the right place – welcome aboard! We’re glad we’ve helped you reach a decision. If you answered with B, then MIDFIX might not be the best partner for you because, whilst we do care about affordability, there are bigger concerns in the industry that we aim to address.