As an M&E contractor, it can be difficult to know which pipework insulation block to specify. Should you choose hardwood, phenolic, or mineral wool? As the sector grows towards a compliant and sustainable model, it can be difficult to figure out which factors to compare. This can undoubtedly lead to confusion as it is rare to find an unbiased comparison online.

It was clear this was an issue during a recent conversation with an M&E contractor.

“Pipe insulation blocks are becoming a confusing topic with the variety of options now available. Back in the day, it was just simply hardwood blocks. Yes, they may not have been the most thermally conductive material, but they were strong and did the job. Understandably priorities have changed and we now see phenolic and mineral wool alternatives available.

Whilst it is great to see new alternatives, I am really struggling to find an honest explanation for why I may choose one over another. It would be great if there was objective information available that identifies the pros and cons of each of these options but lets me decide which is right for me.”

This article is our effort to provide an objective source of information showcasing the comparisons between the different pipe insulation blocks available. The approach is simple. We list out the factors that must be considered when specifying a pipe insulation block and describe each type.

Outlined below are the article's key sections (simply click on the section you require)

- What is a hardwood pipe insulation block and why would you specify them?

- What is a phenolic pipe insulation block and why would you specify them?

- What is a mineral wool pipe insulation block and why would you specify them?

- What other factors should be considered?

- BS 5970

- CIBSE CP1 Code of Practice

- Pipe insulation block comparison table

- Glossary

What are pipe insulation blocks?

Pipe insulation blocks (commonly known as insulated pipe supports) are blocks of insulation fitted onto pipework and clamped into place to mitigate heat loss within pipework systems. There are three main types of pipe insulation blocks: phenolic foam, hardwood, and mineral wool.

What factors should be considered when specifying pipe insulation blocks?

To assist us with this unbiased explanation we caught up with Chris Ridge, Technical Policy Manager at the Thermal Insulation Contractors Association (TICA). Chris pointed out several factors that should be considered before an M&E contractor specifies or sources pipe insulation blocks.

“It is important to consider whether the insulated pipe support insert adheres to the BS 5970 standard and whether it complies with the insulation specification. You also need to consider some standard factors such as the blocks reaction to fire (Euroclass) and compressive strength. The location of the pipe support insert should also be considered – if the pipe support is externally located then it should be pre-clad with a suitable weatherproof cladding material that also matches the insulation specification.”

To summarise:

- Whether the pipe insulation blocks adhere to BS 5970.

- What is the insulation system, and does it comply?

- Reaction to fire (UKCA marking & Euroclass fire certification),

- Compressive strength

- The environment surrounding the pipe insulation block.

- Ensure that the pipe support is suitably clad for external weatherproofing where required

To compare pipe insulation blocks it makes sense to look at fire resistance classification, compressive strength, and suitability to different applications/environments.

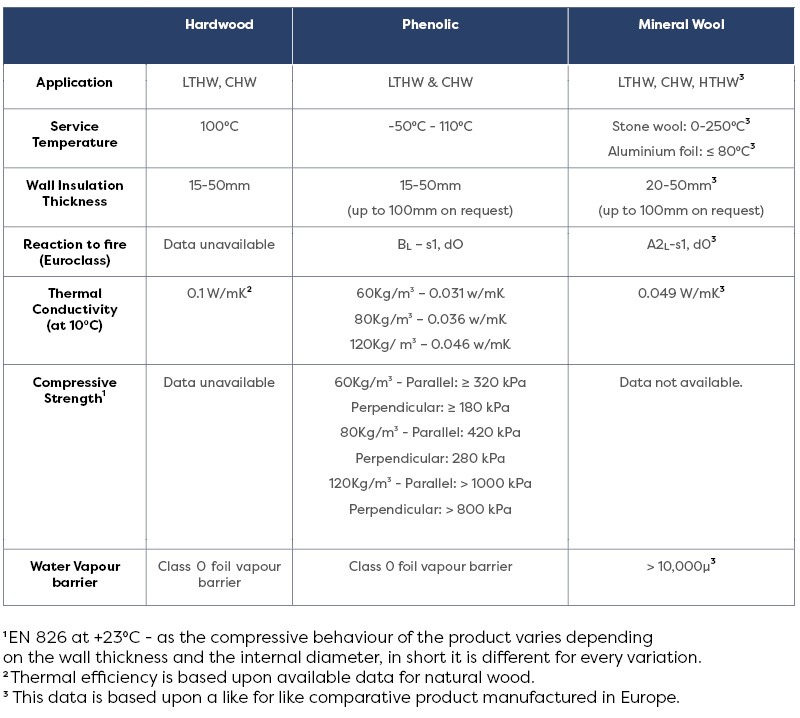

Pipe insulation block comparison table

What is a hardwood pipe insulation block and why would you specify them?

Hardwood pipe insulation blocks are blocks used along with pipe saddles/clamps to ensure that the pipe insulation does not compress at each support location.

Typically, hardwood blocks wouldn’t be specified by a thermal insulation consultant. In very rare instances, hardwood blocks may be specified as a last resort when all other alternatives have been exhausted in their support and strength capacity.

Out of the three options covered in this article for pipe insulation blocks, hardwood blocks are not thermally efficient, which is to be expected due to the fact it is wood. With the growing desire within the sector for a sustainable future, standards such as BS790 outline that wood blocks should not be specified where load-bearing insulation is required for pipes operating above or below ambient temperatures because of their poor insulation properties.

Hardwood blocks would be expected to be in the order of x2 - x3 times the thermal conductivity of the other type of pipe insulation support blocks.

Hardwood blocks are suitable for LTHW & CHW pipework with an upper-temperature limit of 100°C. Despite the poor thermal properties and industry guidance, hardwood blocks are commonly fitted to high-pressure pipework such as wastewater treatment and plantroom pipework.

The real benefit is that they are durable and have superior compressive strength when compared to other insulation blocks. Due to the rigidity of the hardwood material, it can withstand much higher loads/pressures compared with the alternatives and therefore is often the default for mechanical services where pipe insulation blocks need to bear the load of anchors and fixings.

It is also well-known that hardwood blocks should not be used for external environments because they are vulnerable to mould and milldue growth and are susceptible to condensation build-up which will work against any vapor barrier around the block.

There is currently no data available for the reaction of fire for hardwood blocks.

Pipe insulation block comparison table.png?width=724&name=MicrosoftTeams-image%20(255).png)

What is a phenolic pipe insulation block and why would you specify them?

Phenolic pipe insulation blocks are pipe supports manufactured from load-bearing phenolic foam to prevent heat loss or gain through the pipe supports, condensation, and corrosion issues when supporting temperature-controlled water pipes.

Phenolic pipe insulation blocks are specified on LTHW to CHW pipework with temperatures between -50- to 110°C and are typically specified for internal rather than external environments.

From an insulation perspective, they are typically a trusted option. They have a lower thermal conductivity, thus restricting heat loss and heat gain from the pipework.

In cases where pipe insulation blocks are required for heat networks, it is highly likely that phenolic blocks will be specified because of the thermal analysis of a + 75°C LTHW system in compliance to BS EN ISO 10211: 2007 code of practice.”

At the time of writing, the manufacturer of phenolic blocks provided compressive strength data based upon the current CE marking testing regime.

- 60Kg/m3 - Parallel: ≥ 320 kPa & Perpendicular: ≥ 180 kPa

- 80Kg/m3 - Parallel: 420 kPa & Perpendicular: 280 kPa

- 120Kg/m3 - Parallel: > 1000 kPa & Perpendicular: > 800 kPa

Phenolic blocks also hold a fire classification of BL-S1, d0 European standard meaning they compare less than favorably to mineral wool pipe insulation blocks.

As for the BS 5970 there is no mention of specifying phenolic over the other types. Pipe Support Inserts can provide a continuous vapour barrier on below ambient systems with a Class 0 foil vapour barrier.

Pipe insulation block comparison table

What is a mineral wool pipe insulation block and why would you specify them?

Unlike phenolic or hardwood blocks these blocks are made from mineral wool. Mineral wool is made from basalt rock (dark igneous rock formed from the rapid cooling of molten lava), slag, coke (grey hard porous fuel) and recycled stone wool waste.

Mineral wool pipe supports blocks are suitable for LTHW, CHW, medium, and hot temperature pipework, however, they are not advised for sub-zero applications. From a thermal efficiency perspective, they are more thermally efficient than Hardwood but not as efficient as Phenolic insulation blocks.

In many cases, Rockwool pipe supports are specified as a specific component of a Rockwool system.

In terms of reaction to fire the standard Rockwool ROCKLAP product is A2 rated (see glossary for definition). The stone/mineral wool can work with temperatures from 0 – 250°C.

Pipe insulation block comparison tableWhat other factors should be considered?

It is important to remember that pipe support specifications are often directly affected by the insulation specification. Early engagement is key and It is best practice for the M&E Contractor to co-ordinate with the thermal insulation contractor to confirm the type and thickness of insulation required on the pipework system before they specify pipe insulation blocks for M&E services. This can help the M&E Contractor to avoid a mismatch of pipework insulation and insulated pipe support inserts, which may negatively impact the thermal efficiency of a building.

BS 5970

The British Standard 5970 is for the thermal insulation of pipework, ductwork, associated equipment, and other industrial installations in the temperature range of -100°C to +870°C. Code of practice. Within the British standard it makes reference to the 'preferred pipe support'.

The preferred pipe support option for both above and below ambient applications is to have a “hanger incorporating load-bearing insulation”. There is also a non-preferred option for above ambient applications, but this involves a further layer of insulation around the pipe support junction and up the threaded rod.

BS790 also states that wood blocks should not be used. Recommended good practice is for contractors to seek insulation manufacturer guidance for pipe support applications for pipes larger than 200mm NB. This is particularly important in plant room situations where there may be an increased presence of additional pipework equipment (e.g. valves) thus adding to the loading of the pipework. In this case, woodblocks should only be used when it can be evidenced that the insulation manufacturer alternative cannot be engineered to meet the load requirements.

.png?width=724&name=MicrosoftTeams-image%20(255).png)

Finally, it is important for an M&E contractor to consider the installation factors.

- Pipe insulation blocks should have a pipe bracket around them.

- Pipe support blocks should match the thickness of the insulation on the pipe system.

- Pipework may need to be bracketed more regularly and load bearing pipe supports may need to be specifically manufactured at longer lengths or increased densities if the pipe sizes are above 200mm.

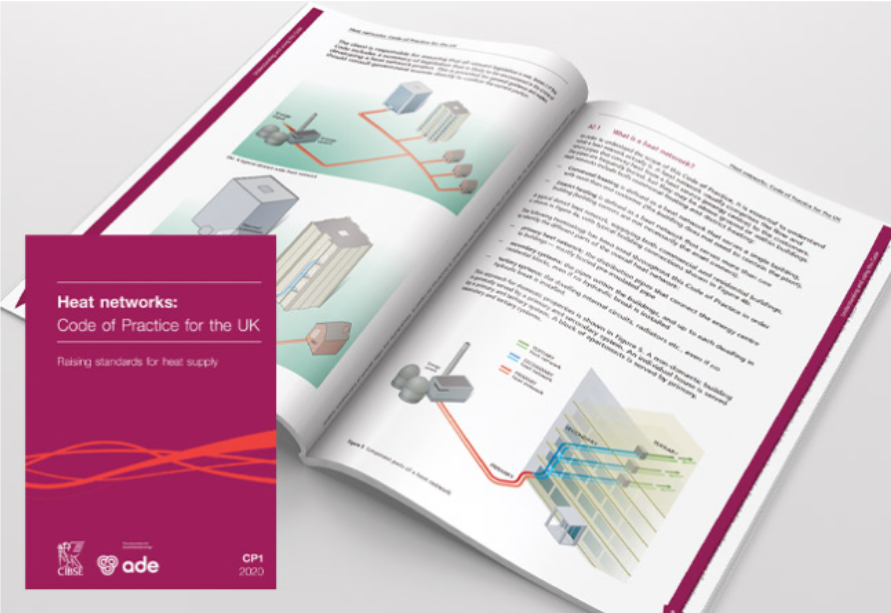

CIBSE CP1 Code of Practice

CIBSE CP1 Code of Practice released in 2020 (CIBSE, 2020) stated that the minimum pipe insulation thickness should be 50mm, bearing this in mind make sure that the pipe insulation block specified is large enough to accommodate.

CP1 also stipulates a targeted heat loss of 100W/dwelling. The published thickness tables are only minimum insulation thicknesses, and they may have little bearing on what is required from an insulation system to meet the targeted 100W/dwelling heat loss figures. This means that many Heat Network projects may require insulation blocks exceeding 50mm thicknesses. Early engagement between the M&E Contractor and the Thermal Contractor is required to ensure that the right size/type of pipe support is installed to ensure compliance.

Pipe insulation block comparison table

The manufacturer of mineral wool blocks is currently undergoing independent UK CA testing and as such the data is based upon a comparative product manufactured in Europe. This article will be updated when the relevant data is available.

The manufacturer of phenolic blocks stated that current compressive strength testing has been conducted in Germany in line with our current CE Marking testing regime but UK CA marking testing is currently ongoing, the table above will be updated once the relevant data is available.

Conclusion

To specify pipework insulation blocks the factors, listed in the article must be considered. It comes down to the suitability of the pipe insulation block for a given environment, abiding with the latest codes of practice, and engaging with a thermal contractor and the supply chain to ensure both the pipework insulation and the insulation blocks match up to optimise the thermal efficiency of the pipework system.

The representative at TICA, Chris Ridge concluded: “It is perhaps also important to remember why we use insulated pipe supports in the first place. Load bearing pipe supports are of course necessary for continuity of the vapour barrier on below ambient applications.

Pipe supports should also be used to mitigate against heat losses on above ambient systems - this is becoming increasingly important on Heat Network projects where there is a growing understanding of the importance of plugging every gap in the system to reduce overheating issues.”

REFERENCES

CIBSE (2020) CPI Code of practice, accessible: [https://www.cibse.org/knowledge/knowledge-items/detail?id=a0q3Y00000IMrmGQAT]

Peroni (2013) EN Reaction to Fire Classification, accessible: [https://www.peroni.com/lang_UK/_download/EN_Reaction_to_Fire_Classification.pdf]

Thermal insulation of pipework, ductwork, associated equipment, and other industrial installations in the temperature range of -100°C to +870°C. Code of practice Available: [https://bioresources.cnr.ncsu.edu/resources/determination-of-thermal-conductivity-properties-in-some-wood-species-obtained-from-turkey/]

Glossary:

LTHW: Low temperature, Hot Water.

CHW: Chilled Water Systems

BS 5971: British Standard for the thermal insulation of pipework, ductwork, associated equipment and other industrial installations in the temperature range of -100°C to +870°C. Code of practice.

Reaction to fire: the behaviour of the materials when exposed to heat or fire. The reaction of the pipe insulation block to fire based is upon the Classification according to European Standards EN 13501-1.

A2-s1, d0 = limited combustibility, little or no smoke, no droplets.

B-s1, d0 - combustible materials - very limited contribution to fire. 'B' = ranges from very limited to medium contribution to fire, 's' = for smoke emissions levels 1 (absent/weak) to 3 (high). 'd0' = relates to the number of flaming droplets and particles that are produced within the first 10 minutes of fire exposure. 'd0'= no droplets.

Compressive strength: this is the amount of pressure a particular pipe insulation block can take over a given material density. This is particularly important for high-pressure pipework.

Thermal conductivity: a material's thermal conductivity is the number of Watts conducted per metre thickness of the material, per degree of temperature difference between one side and the other (W/mK) technically known as the 'lambda value' (λ). As a rule of thumb, the lower the thermal conductivity the better, because the material conducts less heat energy.