In the M&E (Mechanical & Electrical) landscape, where safety and efficiency play pivotal roles in operational success, the importance of choosing the right rooftop access solution cannot be overstated. MX-R Access is a range of rooftop solutions that emerge as frontrunners in this domain, offering benefits that extend beyond access.

This comprehensive analysis aims to dissect the financial implications and rewards of integrating MX-R Access into your business operations, covering initial outlays, ongoing costs, and the myriad of savings opportunities it presents.

- What is MX-R Access?

- What is MX-R Access Low Level?

- Purchase Price

- Installation Costs

- Long-Term Cost Savings

- Conclusion

However, before we begin…

What is MX-R Access?

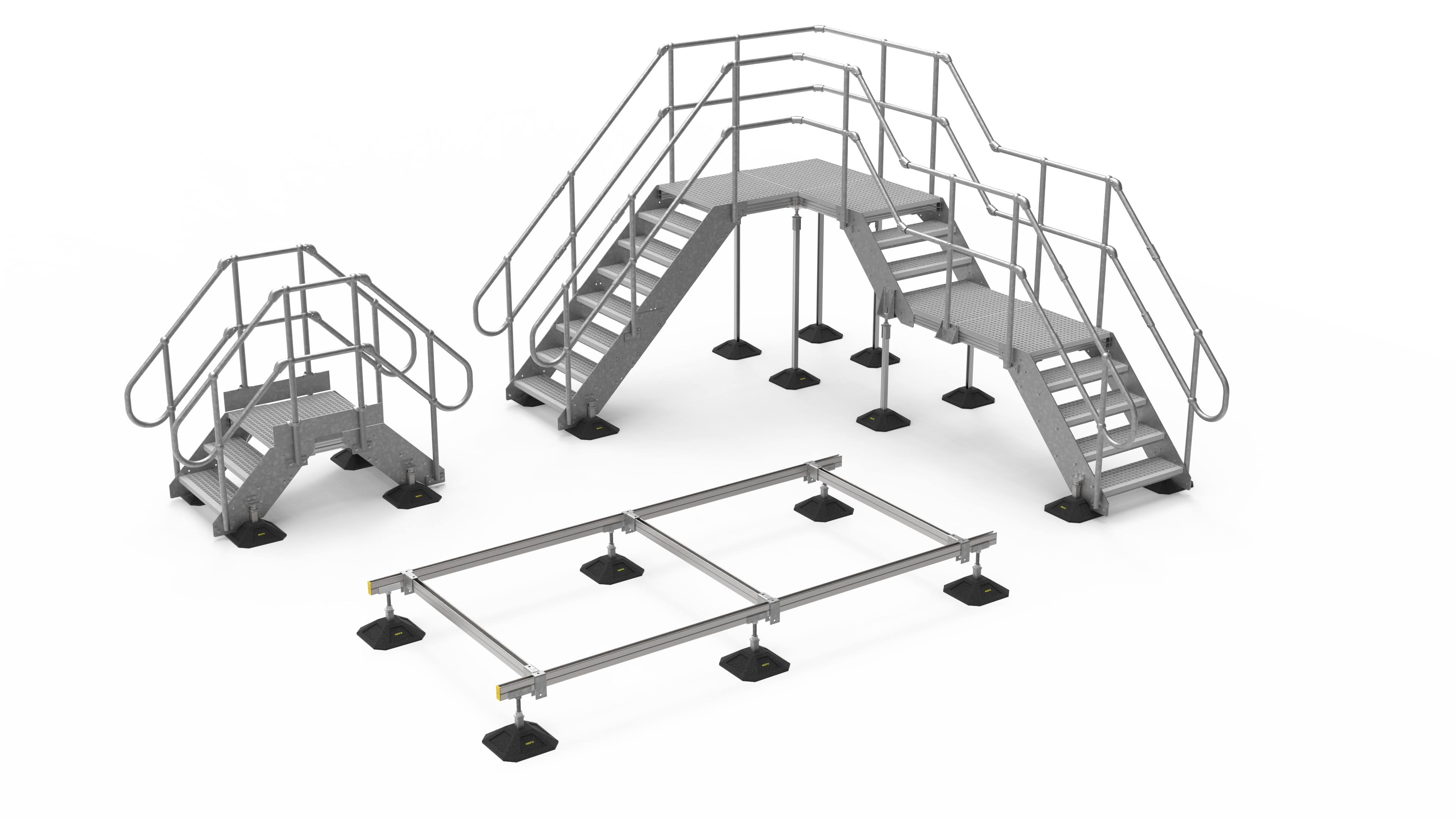

MX-R Access is an MX channel-based, modular rooftop access system designed to give safe and compliant access to workers maintaining or inspecting rooftop services like air conditioning units, ductwork, pipework etc. It is designed to be an adaptable, easy-to-configure, and a bespoke solution that is compliant with BS ISO 14122:2016 standards. The system includes a variety of access solutions such as step-overs, walkways, stairs, and access platforms, each designed to provide safe passage over obstacles, protect the roof and workers, and facilitate easy access to essential rooftop equipment for inspection and maintenance tasks.

What is MX-R Access Low Level?

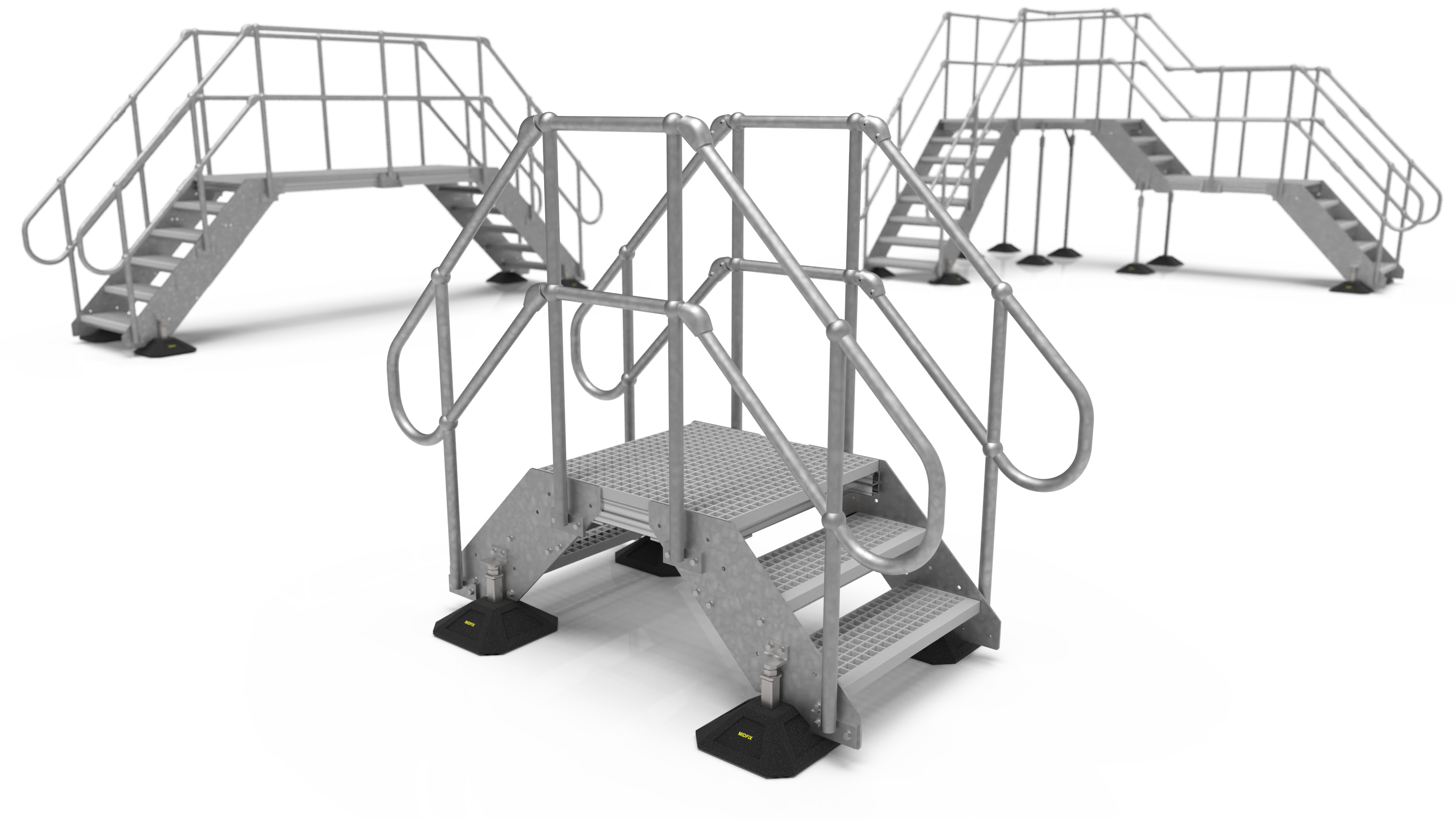

MX-R Access Low Level is an extension of the MX-R Access range, specifically designed for situations requiring small clearances on rooftops. The MX-R Access StepUp is a variant optimised for these smaller clearance heights, offering a cost-effective solution for smaller access requirements. It maintains quality and compliance, features adjustable legs, fast installation, and affordability. StepUp is designed for situations where obstacles are lower than 360mm, making it a more budget-friendly option compared to the standard MX-R Access and is available with or without handrailing. There is also the MX-R HopOver version, which is for simple bridges up to 187mm clearance height and up to 1m platform length as standard, with bespoke requirements met on request.

Purchase Price

Frequently on construction sites, we observe the informal use of wooden pallets as temporary steps and makeshift bridges to traverse pipework and ducting for maintenance purposes. Although this approach may seem cost-effective compared to investing in a purpose-made rooftop access system, it carries significant risks. The potential for injuries and the likelihood of failing to meet safety standards can result in considerable financial repercussions down the line.

MX-R Access addresses these concerns directly. While its upfront material costs might surpass those of ad-hoc solutions, the long-term advantages and the assurance of safety it provides justify the investment.

Bespoke Off-The-Shelf Design

MX-R Access, although not the least expensive option available for rooftop access, stands out as one of the most cost-effective for something that is offered completely bespoke yet readily available.

The MX-R Access range allows for the creation of bespoke solutions using off-the-shelf components, thereby eliminating the need for any custom, complex and expensive parts on long lead times. This approach allows for the creation of a platform solution using MX channel cut-to-length and standardised MX-R components that are readily available and stocked in-house to provide a lean solution available for next-day delivery.

Here are some of the access requirements that MX-R Access can be adapted to:

- Raise up to 7 steps and up to 1.5m of clearance.

- Raise to a second platform height.

- Turn corners.

- Accommodate taller platforms with bracing.

- Up to 5 degree of roof pitch adaptability.

This approach ensures that each rooftop access platform is precisely tailored to meet the unique needs of your site. This not only guarantees a perfect fit every time, but also prevents you from wasting resources on unnecessary materials.

MX-R Access Low Level

Another clever way in which MX-R Access optimises its design is with its extended product range- MX-R Access Low Level (including MX-R StepUp and MX-R HopOver), which is specifically designed to cater to scenarios where services are situated below a height of 360mm. MX-R Low Level is a far more compact iteration of MX-R Access, and selectively optimises its design by omitting features found in the broader MX-R Access range, such as handrails, kick plates, and a stringer. It incorporates only the elements that are crucial for adhering to safety standards, steering clear of unnecessarily over-engineered solutions that may be superfluous for low-clearance heights. While these variants do not compromise the safety, compliance, or quality of your rooftop access platform, it does make sure that you are only paying for precisely what you need.

Installation Costs

The installation process is a critical phase in the integration of any rooftop access system, where time and labour efficiency can significantly impact overall project costs and timelines. Traditional rooftop access solutions often require extensive installation efforts, involving significant manpower and prolonged site disruption. MX-R Access, however, stands apart in its approach to installation, exemplifying efficiency and minimising the necessary labour and time investment, thereby offering a more cost-effective solution from the outset.

Reducing Installation Complexity

MX-R Access has been meticulously designed with ease of installation at its core. MX-R Access can be prefabricated, meaning that much of the assembly work has been completed before the components even arrive on site, thereby eliminating the need for any costly and time-consuming onsite fabrication works. The system's modular nature allows for quick assembly, significantly reducing the complexity typically associated with installing rooftop access equipment. This streamlined process not only cuts down on the time required to make the rooftop accessible but also diminishes the need for specialised labour, which can often be a considerable expense in construction projects.

In comparison, temporary rooftop access solutions can often require more time to construct on-site and may frequently encounter issues and malfunctions.

On-site Adjustability

MX-R Access's height adjustability (up to 100mm for MX-R Access and 50mm for MX-R Access StepUp) is a critical feature that enhances both installation efficiency and the system's overall utility. This adjustability means that components can be tailored in real-time to suit specific site variables in case the height of the services differs from the initial specifications. The ability to adjust on the fly not only accelerates the installation process but also ensures a precise fit, eliminating the need for costly post-installation modifications.

Long-Term Cost Savings

Investing in MX-R Access transcends immediate needs, offering long-term benefits that significantly impact safety, compliance, and financial health. The system's design principles—modularity, adjustability, durability, and a steadfast commitment to safety and compliance—combine to create a solution that not only meets the present requirements but also adapts to future changes, withstanding the test of time, and ensures ongoing regulatory compliance.

Modularity and Adjustability

The flexibility inherent in MX-R Access's modular and adjustable design is pivotal to its enduring value. As operations expand or shift, MX-R Access can seamlessly adjust to these changes. It’s design supports straightforward dismantling, reconfiguring, and adjusting, all while maintaining its structural integrity, to align with any new requirements, whether they involve integrating new services, accommodating expansions, or modifying access paths.

This design philosophy means that when the current setup is no longer necessary, the components can be quickly taken apart without any damage, allowing them to be reused or repurposed for future needs. By offering the capability to tailor and reshape the system to meet the unique demands of any site, MX-R Access can serve multiple purposes or be moved to different locations, maximising the return on investment, and minimising the need for additional spending on new access solutions.

Safety and Compliance

The construction industry has a critical need for reliable maintenance access solutions on job sites to prevent workplace accidents and injuries, necessitating a move moving away from temporary, often unsafe practices. This requirement guided the development of MX-R Access, a system meticulously designed with a focus on safety and compliance, adhering to the health and safety standards established by BS ISO 14122.

Here are some of the essential requirements of the BS 14122 that the MX-R Access product range is designed to meet:

- It has been tested against a 1.5kN of force (152.96kg) load bearing capacity, and therefore, comes with reliable test data to evidence this.

- It has rubber feet that spread the load out evenly without penetrating the roof membrane.

- All metalwork comes with a hot dip galvanised finish to withstand harsh environmental conditions.

- The width is kept to a standard of 800mm.

- It utilises 38mm, non-slip GRP grating as standard.

- Specifically for MX-R Access platforms, additional safety features such as handrails, kick plates and a heavy-duty stringer are included, as these platforms exceed the 500mm threshold. Handrails can also be added to MX-R Access Low Level if desired.

Integrating MX-R Access into construction and maintenance projects is not just about adhering to safety and compliance standards; it's also a strategic investment that proves to be cost-effective in the long run. The initial outlay for a system that meets the stringent requirements of BS ISO 14122, as MX-R Access does, offers significant financial advantages over time compared to the use of makeshift solutions like wooden pallets.

Reduced Liability and Insurance Costs: By ensuring a high level of safety and compliance, MX-R Access minimises the risk of workplace accidents and injuries. This not only protects workers but also significantly reduces the potential liability for construction companies.

Durability and Reduced Maintenance Costs: The durable design of MX-R Access, including features like hot-dip galvanised metalwork and non-slip GRP grating, ensures that the system withstands harsh environmental conditions without frequent need for repair or replacement. This resilience translates into lower maintenance costs over the lifespan of the access system, in contrast to temporary solutions that may require regular replacement or repair.

Compliance and Avoidance of Fines: With regulations becoming increasingly stringent, the cost of non-compliance can be substantial, including fines and work stoppages. MX-R Access has been rigorously tested to evidence its robust load-bearing capacity. This testing is crucial, not only to meet the BS ISO 14122 standards but also to comply with the 2022 Building Safety Act and the associated 'Golden thread' legislation, which requires contractors to demonstrate the performance of their installations with reliable test data.

Ensuring compliance from the outset with a system like MX-R Access avoids the potential financial repercussions associated with failing to meet safety standards.

Enhanced Reputation: Investing in a system that prioritises safety and compliance demonstrates a commitment to worker welfare and regulatory adherence, enhancing a company's reputation. This can lead to more business opportunities, as clients prefer to work with companies that maintain high safety standards.

Conclusion

The financial analysis underscores the value of MX-R Access beyond its initial purchase price, highlighting the reduced liability, lower maintenance costs, and avoidance of fines associated with non-compliance. The system's modularity and adjustability further ensure that it can evolve with the changing needs of a business, offering a scalable solution that maximises return on investment over time.

Investing in MX-R Access is not merely a decision about selecting an access platform; it is a strategic move towards building a safer, more efficient, and compliant operational environment. In a landscape where safety and compliance are now becoming legislation, MX-R Access emerges not just as a cost-effective option, but as the optimal solution for contractors aiming to streamline their construction projects while safeguarding their most valuable asset: their workers.