In the competitive world of construction and building management, the choice of materials and systems can significantly impact both budget and functionality. The MX-R modular system, designed for rooftop plant support frames, stands out as a potentially cost-effective and versatile solution.

This article delves into a comprehensive cost versus benefit analysis of MX-R support frames, comparing it with alternatives like traditional welded supports or even modular box section rooftop support frames. We aim to provide insights into MX-R's affordability, efficiency in installation, and long-term value, helping professionals make informed decisions for their specific construction needs.

What is MX-R?

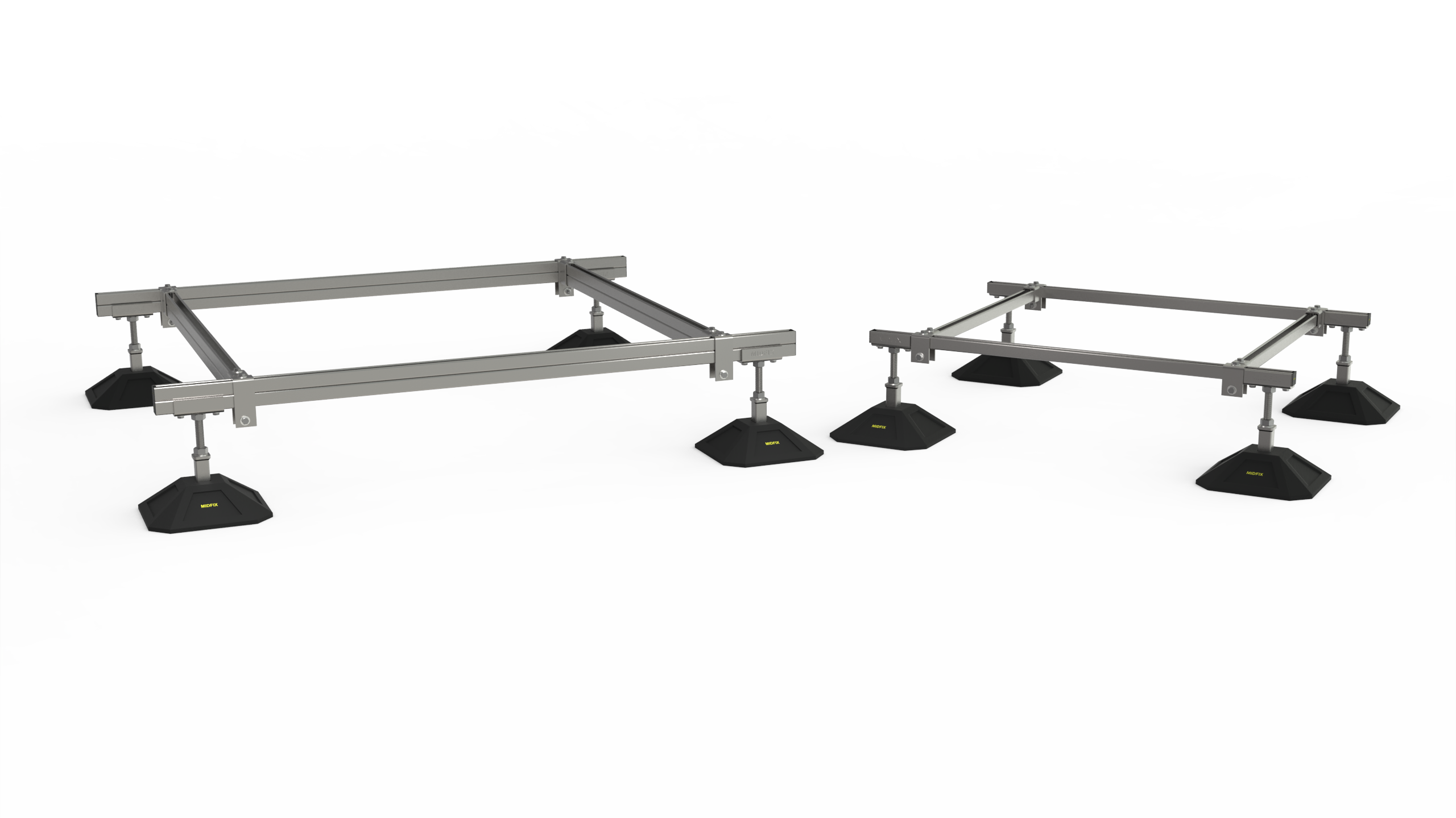

MX-R is a new approach to supports and access provisions for rooftop building services installations. The rise in HVAC, pipework, cabling and solar panels being installed on roofs makes roof supports an increasingly important consideration in terms of cost, availability, and ease of installation.

It is not uncommon for roof support provisions to be inadequately considered resulting in costs that often exceed the budget. Access provisions are often left until the end of the project and then required in a hurry. MX-R Roof Support System is an innovative solution that covers all aspects of non-penetrative, free-standing roof supports and access products. It is designed to enable rooftop products to be configured to the exact requirements of the project, more economically and off-the-shelf.

Upfront Costs

When considering the implementation of any rooftop support system, understanding the initial purchase cost is crucial. The MX-R system, known for its affordability and efficiency, stands out in this regard due to several key factors that contribute to its lower upfront costs.

MX-R versus Modular Box-Section

Modular box-section rooftop support frames, constructed primarily from steel, tend to be more expensive. Steel, as a material, carries higher manufacturing and processing costs. In contrast, the MX-R system, with its less expensive channel-based design, offers a more budget-friendly alternative (though also made of steel). The material choice of channel in MX-R not only affects the raw material cost but also impacts the transportation and handling expenses, as channel is lighter than the steel structures used in modular box-section.

The MX-R system's design is optimised to use minimal material while maintaining structural integrity. This efficiency in material usage directly translates to lower manufacturing costs, thereby reducing the initial purchase price. In comparison, modular box-section frames usually use more material to provide a high load bearing capacity, leading to higher upfront costs. So, in cases where you are not exceeding the limitations of channel, you’d likely be overengineering and overspending by opting for a modular box-section frame. In the majority of cases, back-to-back channel would be sufficient to carry most rooftop loads, which can be achieved by MX-R.

MX-R versus Traditional Welded Options

Typically, traditional rooftop supports and access products are a hybrid of off-the-shelf frames and stepovers, and bespoke designs and fabrications where standard products are not suited to the application. So, while the initial cost of purchasing material for traditional rooftop systems may seem lower, the overall expenses must account for additional processes like welding, jigging, and handling. Outdoor applications necessitate hot-dip galvanisation, further increasing expenses due to the finishing process and transportation to the galvanising facility. Moreover, labour costs, as well as the expense of specialised tools like broaching tools and mac drills, contribute significantly to the total cost.

In comparison, MX-R's unique 'bespoke off-the-shelf' design significantly enhances its cost-effectiveness compared to traditional welded systems. This approach allows for the use of standardised components that are readily available and stocked in-house, to create a bespoke support frame or access solution to suit your exact requirements. Channel is cut to length to suit your order and combined with our suite of MX-R components to deliver a lean solution with fast next-day delivery. This contrasts with the often custom, complex, and expensive parts required for traditional welded systems.

The MX-R system's adaptability to various AHU or plant lengths without the need for bespoke parts or any welding streamlines the installation process, further reducing upfront costs.

Time and Labour Considerations

In the construction industry, time and labour considerations are crucial for the success and cost-effectiveness of any project. This section will explore how the design features of MX-R, such as its ease of installation, no-welding requirement, and adjustable design, contribute significantly to reducing time and labour costs.

Procurement Process

The MX-R roof support system is designed to offer a 'bespoke off-the-shelf' solution, meaning it can accommodate various AHUs/plant sizes without the need for bespoke, complex, or expensive components. This feature addresses common issues related to long lead times for custom parts. MX-R ensures that components are standardised and stocked, allowing for next-day delivery. This aspect significantly streamlines the procurement process, leading to quicker acquisition times and reduced administrative burden.

Installation Process

One of the primary advantages of an MX-R support frame is its ease and speed of installation. The design of the frame, free from box sections, complex connections, and sliding parts, is focused on user convenience. This user-centric approach means that assembling an MX-R frame is straightforward and efficient, allowing for easy installation without the need for specialised assistance or extensive training. This contrasts with more complex and heavy systems that might require specialised welding skills or other technical expertise. As a result, this simplicity keeps on-site labour costs and installation time low, making it a cost-effective choice for projects.

The adjustable nature of MX-R also ensures that any onsite differences and changes can be accommodated easily during installation, without the need for off-site fabrication, welding or cutting. The legs are height adjustable up to 100mm to adapt to varying roof pitches and platform heights, and cross rails can be repositioned if necessary to accommodate any loading challenges that may arise. This contributes to overall project efficiency and cost-savings.

Long Term Savings

Long-term savings are crucial in construction and infrastructure projects for several reasons. Initially, while upfront costs are often a primary focus, the long-term costs of maintenance, repairs, and potential system replacements can significantly impact the overall financial health of a project. Systems like the MX-R that offer durability and require less frequent maintenance can lead to substantial cost savings over the lifespan of the building. Moreover, investing in systems with proven longevity can enhance the value and functionality of a building, making it a more attractive proposition for future tenants or buyers. Therefore, considering long-term savings is vital for sustainable and financially sound building management.

Safety and Compliance

MX-R frames, specifically designed for rooftop plant supports, offer a focused solution compared to more generic modular box-section and traditional welded frames. This specialisation ensures safety and compliance, which are key under the 2022 Building Safety Act. MX-R's reliable test data, demonstrating its ability to bear heavy-duty building services like AHUs, is a significant advantage. Compliance and safety assurance are critical, minimising risks like accidents and legal liabilities.

Additionally, MX-R's comprehensive test data aids in efficient regulatory documentation and inspection processes, providing a clear record for future modifications. In contrast, traditional steel frames may sometimes be of uncertain quality and origin, posing potential risks in compliance and safety.

Maintenance and Durability

As mentioned, the MX-R roof support system is engineered with a focus on safety and compliance, ensuring its longevity. It features a verifiable load capacity, backed by comprehensive testing data, which guarantees that the rooftop support frames can reliably handle the designated service loads. This robust construction minimises the risk of failure, providing contractors with confidence in the system's durability and stability. This reduces the costs associated with frequent maintenance, repairs, and reworks in the future.

The design of the MX-R system incorporates components that are hot-dip galvanised, enhancing the support frame's resistance to various environmental factors such as weathering and corrosion. The galvanised coating forms a protective barrier, which not only prolongs durability but also maintains the structural integrity of the system under various climatic conditions, extending its lifespan. As you can imagine, this is particularly beneficial for rooftop applications, where exposure to harsh environmental conditions is a common challenge.

The adaptability of the MX-R system significantly contributes to its longevity. Its flexible design allows for easy adjustments to accommodate various rooftop layouts and equipment changes over time. This adaptability means that the system can evolve with the building's needs, reducing the necessity for complete system replacements. By accommodating future modifications and upgrades with minimal structural changes, the MX-R frames remain functional and relevant for longer periods, thus enhancing its overall lifespan and value as an investment.

Environmental Costs

The MX-R system's adaptability significantly enhances its environmental benefits. Its ability to conform to various rooftop designs reduces the need for specialised manufacturing and replacements, which often carries a larger environmental footprint. This flexibility in adaptation not only decreases waste during installation but also allows for the reuse or reconfiguration of components across different projects, promoting a sustainable use of resources.

Moreover, the design optimisation aspect underscores sustainability. By strategically using materials and design methods, the MX-R system is optimised to give you just what you need, with as little material usage as possible. This conscious approach to material usage and waste reduction aligns with the principles of sustainable construction, making the MX-R system a favourable option for eco-conscious projects.

All in all, these systems align with environmental regulations and standards, potentially qualifying for green building incentives and avoiding penalties associated with environmental non-compliance.

Conclusion

In conclusion, the MX-R modular rooftop support system emerges as an impressively viable and efficient option in the realm of rooftop plant support frames, especially when evaluated against traditional welded supports and modular box-section frames. The detailed cost-benefit analysis presented in this article highlights MX-R's competitive edge in various aspects, ranging from upfront costs to long-term savings and environmental considerations. Its benefits extend beyond the immediate financial savings, encompassing ease of installation, safety, compliance, long-term durability, and environmental responsibility. This analysis makes a strong case for considering the MX-R system as a strategic investment in any construction or building management project, offering value that is both immediate and enduring.