After reading the guidance set out on this page you will have an understanding of the following, simply jump to your preferred section. Alternatively, feel free to read our complete guide on anchor/fixing compliance.

According to BS 8539 what information should be supplied?

Under BS 8539 what are the responsibilities of the supplier?

Why would the specified anchor not arrive on-site?

Does this mean another stakeholder is liable?

If the new anchor has similar characteristics, then what is the issue?

How does BS 8539 guide us if the specified anchor does not arrive on-site?

BS 8539 and the change management procedure?

Further reading?

How is an anchor supplied in accordance with BS 8539?

Anchors are a small component to which little consideration is frequently given but are absolutely vital to preventing the collapse of the structure or installation that depends on them. As the construction & M&E industry moves towards a compliant, tested, and traceable future, anchor/fixing compliance is critical. The contractors that follow guidance will no doubt lead the way and win the biggest projects.

BS 8539 is quite clear: the specified anchor must arrive on-site. Within the M&E industry anchors are usually left to the last minute and resulting in a higher risk of the specified anchor not arriving on-site.

In our latest sound out episode our anchor expert Stevan discusses the importance of supplying the specified anchor on-site.

According to BS 8539 what information should be supplied to the supplier?

To supply the specified anchor on-site, the manufacturer and their agents should provide:

- All information for the specifier to select the correct anchor, having followed the correct selection criteria.

- Technical catalogues and software

- Installation instructions for the installer

Under BS 8539 what are the suppliers responsibilities?

- Must provide the anchor as specified unless a specific change management procedure has been followed.

- They should take the opportunity to ensure all associated setting equipment is offered to the contractor such as drill bits, hole cleaning equipment, setting tools, torque wrench etc., in order that the installer can install anchors correctly

- Provide installation training or facilitate this being provided by the manufacturer.

- Provide guidance in anchor selection.

- Ensure the change management procedure is adhered to if asked for alternatives.

Why would the specified anchor not arrive?

Issues can often crop up between selecting the anchor and supplying that anchor on-site. Often a third party has been involved in the process and due to commercial reasons or supply issues (due to not enough time being allocated to follow the correct selection procedure) another anchor arrives on-site.

Does this mean another stakeholder is liable?

According to BS 8539 whoever has decided to select a different anchor is now the specifier and as such are liable.

If the new anchor has similar characteristics, then what is the issue?

We need to ensure that the anchor that has been specified (that product code) reaches the site. Breaking the spec of an achor can be a serious issue, for one the installer on-site may not know how to install the new anchor correctly. It is important to know that not all anchors are the same, a few typical differences between one anchor and another include:

- Different manufacturing references

- Unique performance characteristics

- Manufactured differently with specific load characteristics

- Installation instructions

- Approvals may differ

How does BS 8539 guide us if the specified anchor is not supplied on-site?

BS 8539 states ‘the correct anchor must be sourced as specified. If an alternative anchor is proposed, the change management procedure (clause 10) must be followed’

If the contractor is aware of the anchor change, then they must inform the original specifier and ensure it is installed on-site to the manufacturer’s specification.

BS 8539 and the change management procedure

As outlined in BS 8539 the change management procedure must be followed, but what is it?

The change management procedure is referring to clause 10 of BS 8539 guide which states that the correct anchor selection process must be followed.

According to BS 8539, how do I select an anchor?

When selecting an anchor the following factors must be considered -

- Substrate – the manufacturer should advise what substrate is suitable for that anchor, e.g. cracked or non-cracked concrete.

- Loadings – what load can the fixing take and can the fixing perform to the load requirement? Once again, this would be outlined by the ETA.

- Environment – is it a corrosive environment?

- Type of install – is it going to be a through fix or a flush fix?

- Type of anchor – torque-controlled, deformation-controlled, undercut/key or resin.

- What approvals are required for the installation – ETA's etc.

Further Reading

Anchor/fixing compliance for safe selection and installation doesn't have to be complex.

Did you know the Construction Fixing Association provides helpful guidance in relation to BS 8539.

Conclusion

To conclude supplying the correct anchor on-site reduces the risk of on-site anchor installation failure causing an increase in costs and potential missing project deadlines.

Here is an example of anchor installation failure. It reminds us of the importance of ensuring that all anchors specified are taken through the correct selection procedure as outlined in BS 8539.

Our technical experts at MIDFIX can meet all anchor/fixing requirements for construction projects.

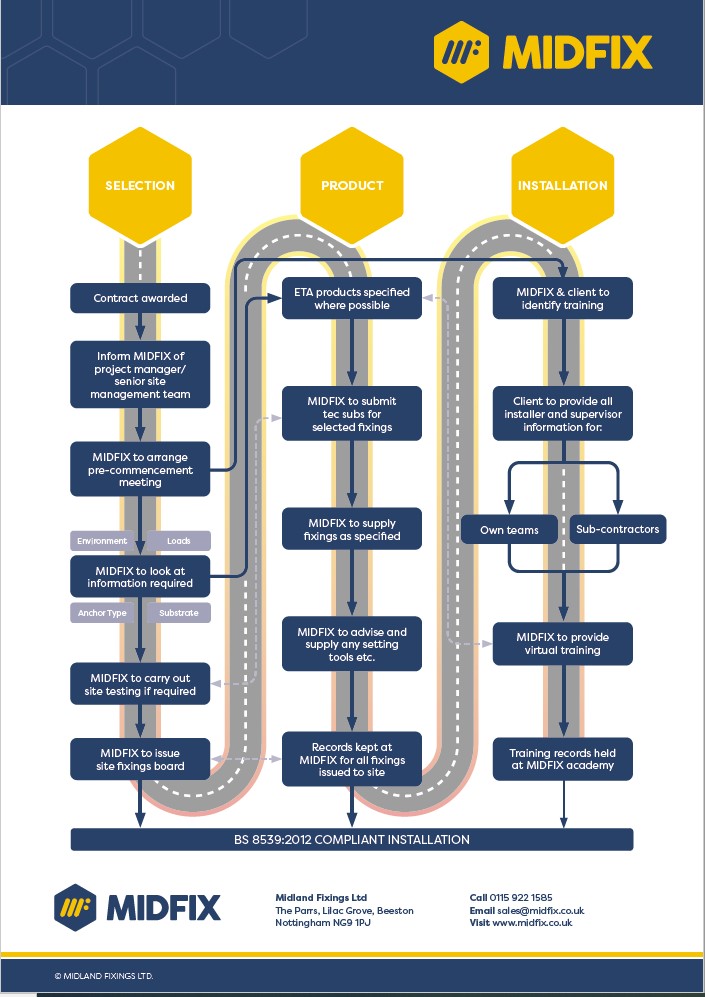

Illustrated below is the MIDFIX roadmap highlighting all of the anchor services.

For anchor certainty on-site:

0115 922 1585

sales@midfix.co.uk

Live Chat – simply click on the hexagon in the bottom right-hand corner to speak to our customer service team (Open Monday - Friday 7.30am - 5pm).