Today we sit down with our technical sales manager – Stevan Grkinic to discuss anchor installation, the British Standard BS 8539:2012, and its impact on M&E contractors.

- Why anchors installed incorrectly can cause assembly collapse

- The key principles of BS 8539:2012

- Anchor selection

- Supply options

- Installations

- Testing

How can an incorrect anchor installation cause assembly collapse?

“When we look at an assembly or bracket usually the weakest link is the anchor. In all my experience I have not seen that many true anchor failures, however, I have seen plenty of brackets and assemblies collapse”

This is mainly due to two reasons:

- The anchor has been installed incorrectly (most common)

- The anchor has been specified wrong in the first place meaning the anchor was never given the opportunity to perform as intended

“Over 80% of the drop-in anchor (wedge anchor) are installed incorrectly” (Construction Fixings Association)

Why did the BS 8539:2012 code of conduct come into practice and who does it impact?

The BS 8539:2012 came into practice in the UK following a couple of potentially fatal accidents. The standard itself is aimed at anchor designers, specifiers, installers, and testers. The main points for the contractor are:

- ETA approved anchors should be used where possible

- The correct anchor must be sourced as specified. If an alternative anchor is proposed, the change management procedure must be followed.

- Installers must be trained on the anchor installation. They must be supervised and upon completion, the installation should be certified by the contractor’s supervisor.

- Site tests in accordance with the CFA guidance notes undertaken by a competent tester.

Which specific areas does the BS 8539:2012 cover:

The BS 8539:2012 standard is focused upon four key areas:

- Selecting the correct anchor

- Supply – helps to ensure that the correctly selected anchor reaches the site

- Install – it guides us in the installation of the anchor

- Test – how do we test that the installation is correct

“No matter the role you play within the supply chain, be it designer, project manager, the BS 8539:2012 standard states that whoever takes for responsibility for selecting anchor is assumed to be the supplier”. Before the specifier selects the correct anchor they need to have the due diligence and work through the following points.

What are the key factors that need to be addressed before an anchor is selected?

Before any anchor can be put into service the following factors need to be considered:

- Substrate

- Loadings

- Environment

- Type of install

- Type of anchorage

- Approvals

How to factor in the substrate when selecting an anchor:

- Concrete – cracked or non-cracked

- Brick is solid or hollow.

- Timber, laminated engineering timbers are quite common, note timber is not covered under BS 8539

- Blockwork is becoming lighter and we are hanging heavier loads on them.

- Plasterboard, again some quite large loads being used on plaster. Again, not covered under BS 8539:2012

- Steel Decking is quite common on-site, if we cannot fix to the entrant where a lindadapter wedge would fit then we need to drill into the substrate behind which is 9/10 concrete.

Specifically, what does the BS 8359:2012 say when it comes to distinguishing between cracked/non-cracked concrete?

Concrete is a fantastic material under compression but very poor under tension. You will often find a reinforcing bar to support the tension.

Anchors that are qualified to be used with cracked concrete are expected to function reliably in the expected widths of cracks developed. As a result of tensile stresses in concrete structures designed in accordance with BS EN 1992. In the region of an anchor, the concrete might be cracked or non-cracked.

The BS8539:2012: gives us an answer for that – if you don’t know, you have to assume its cracked unless you can prove otherwise and that’s usually via the structural engineer on-site.

“Typically a cracked approved anchor can be anywhere from 30% performance lower than its uncracked equivalent but if we were to fit an anchor in a cracked zone and it wasn’t designed for that zone we could lose up to 80% of the performance of the anchor”

This is why it is pivotal that the specifier understands if the concrete is cracked or uncracked and where they are making that actual installation.

The ETA also looks at cracked and non-cracked approvals with options 1 to 6 covering cracked and 7 to 12 non cracked.

Why would concrete be cracked?

Concrete is likely to be cracked from a variety of causes including:

- Stress conditions inherent in the structure, those induced by characteristic permanent actions and characteristic variable actions

- Thermal movements, shrinkage, and the restraint of deformation.

How does the loading weight affect the choice of anchor?

Once again it is the responsibility of the specifier to understand the type of load that is being applied to the anchor. Different factors determine the choice of anchor.

- Is it static or dynamic

- The magnitude of the load

- The direction (tension, sheer) of the load

- Duration of the load (specifically what load is applied to the anchor).

How does the environment surrounding an anchor effect the selection?

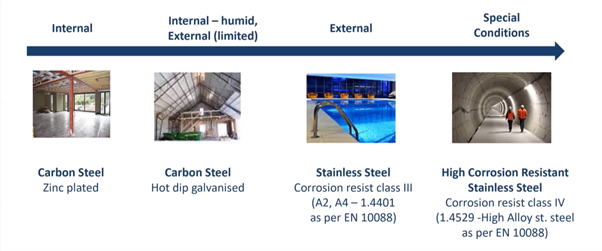

The specifier needs to consider the environment in which the anchor is being asked to perform.

Most internal applications will be zinc plated, however, once we remove the walls for a multi-story car park for example the environment has altered. Therefore we need to be looking at alternative finishes such as hot dip galvanised (HDG) or Stainless Steel.

Certain applications such as swimming pools need very careful consideration as chlorine attacks the passive film on stainless and can cause internal cracking which can cause anchor failure.

Anchor installation fail

Anchor installation fail

What factors need to be considered around the installation of an anchor?

Is it a flush fix or through fix or post-installed?

- Flush fix – pre-install anchor into the substrate than apply the fixture afterward

- Through fix – can be fixed straight through the fixture into the substrate (quicker install / less accuracy)

The type of installation will determine the suitability of different anchors.

How does the specifier select the correct anchor for the right location?

This stage is very important for the specifier to understand. They will need to understand basic anchor principles in order to specify the right one. Here are the four main type of anchors:

- Torque controlled

- Deformation controlled

- Undercut/key (concrete screw)

- Resin

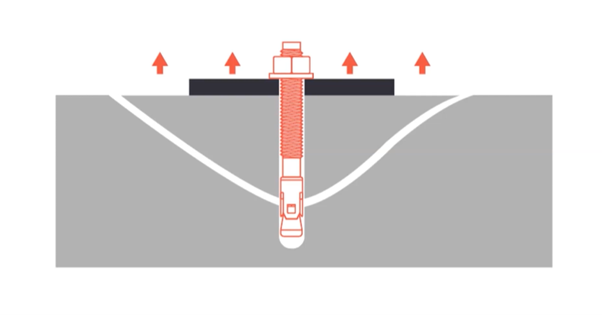

Out of the four anchor types above two of them, the torque controlled through-bolt and the drop-ins, impose large stress into the substrate. This can cause issues if installed in the wrong locations. The undercut (concrete screw) and resin impose very little stress in the substrate and can be used closer together and closer to edges of slabs than the other two types.

According to the BS 8539:2012 which approvals are required when choosing a type of anchor?

BS 8539 specifies that whether it is possible it is important to use an ETA (European Technical Assessment) rated anchor. The ETA is a harmonised independent set of tests and standards adhered to by all reputable anchor manufacturers. The ETA test anchors in different substrates with varying loads and finally gives them the performance figures we use for the specifier to make the selection purposes. It is awarded following comprehensive testing to framework documents, which explore the functionality of the anchors in a wide range of site conditions.

The specifier needs to understand such issues as multiple-use and what this means as the majority of anchors are multiple-use, they also need to take into consideration other water and fire ratings.

How does the BS 8539:2012 ensure that the correct anchor is specified and reaches the site?

Under BS 8539 the manufacturer and their agents should provide the specifier with:

- All information for the specifier to select the correct anchor (technical specification and how to install the anchor)

- The supplier plays an important role – such as advice – must provide the anchor as specified and if they change the specification they need to ensure that the trained management procedure is followed (the six points mentioned earlier)

- Technical catalogues and software

- Installation instructions for the installer

- All associated setting equipment is offered to the contractor (torque wrench & setting tools etc)

Your supplier also has responsibilities:

- Must provide the anchor as specified unless a specific change management procedure has been followed.

- Provide installation training or facilitate this being provided by the manufacturer.

- Provide guidance in anchor selection.

- Ensure the change management procedure is adhered to if asked for alternatives

- Recommended load (ETA state this as the safe working load).

How does the BS 8539:2012 ensure that anchors are safely installed?

BS 8539:2012 states that anchors should be installed and supervised by competent individuals. BS 8539 defines competent as:

“Suitably trained and qualified by knowledge and practical experience, and provided with the necessary instructions, to enable the required task(s) to be carried out correctly”.

BS 8539:2012 States that testing is not required if an ETA anchor has been used and installed and supervised by competent/trained individuals.

According to the BS 8539:2012 what type of anchor tests are required after the installation of anchors?

There are generally two different types of tests called for within M&E contracting:

- Proof Testing (often referred to as a pull test). These are carried out after installation by the contractor and they check the quality of the installation.

- Allowable load test: where the application involved is not covered by a relevant ETA, or the strength and condition of the base material are unknown, with no published data.

- Proof testing is generally 1 in 40 tested up to a maximum of 1.5 x recommended load. This means the anchors can stay in service. We are only testing the installation quality as the anchor performance is already known via the ETA.

- Suitability testing will inevitably damage the substrate as anchors may require testing to ultimate load.

How has the BS 8539:2012 affected the M & E industry as a whole?

The BS 8539 standard came into practice as due to the inability of specifiers on-site to go through the correct due diligence when installing an anchor. This led to two issues:

- Various cases of potentially fatal accidents due to the collapse of assemblies and brackets

- The reputation of key construction companies and their contracted principle contractors becoming damaged

The BS 8539 puts the onus on the specifier - ensuring they follow due diligence and safely supply, install, and test all anchor fixings. The code of conduct is there to reduce the risk of any structural collapse and potentially fatal accidents.

If challenged, can the specifier demonstrate that the structure you have installed can take the service load applied to it and that the supports and fixings are fit for the purpose?

MIDFIX are experts in onsite and offsite supports for the mechanical and electrical industries, delivered through design, engineering, fabrication, and industry training. For over 40 years MIDFIX has been supplying fixings and fasteners to support world-famous structures dotted across the UK’s landscape. It should come as no surprise that we have built up a deep level of knowledge and experience in specifying the right fixings for the correct application.