As the industry becomes ever more regulated, there is a growing need for every asset delivered to site to have traceable and evidenced performance data. Moving forward contractors will require, not just 'hear say' but a guarantee that those anchors/fixings delivered to the site will support the load applied to them.

A particular challenge for the M&E sector is both time constraints, rising material prices, and supply issues so it is no wonder that sometimes an anchor originally specified on-site does not arrive. This is referred to as 'breaking spec'.

It is recommended that for anchor/fixing compliance BS 8539 must be referred to in this situation.

What does BS 8539 tell us about breaking spec for another anchor?

In our latest sound out episode, Stevan Grkinic, our anchor expert sits down to discuss, according to BS 8539 can you break the specification of an anchor for another similar anchor?

The BS 8539 clearly states:

“The correct anchor must be sourced as specified. If an alternative anchor is proposed, the change management procedure must be followed”

What are the main reasons why an anchor specified may not be the one supplied on-site?

It often comes down to the fact that one of the stakeholders decides, due to commercial reasons, not to supply that anchor. If this happens then this stakeholder becomes the specifier under BS 8539 and therefore carries the responsibilities of following the right procedures as outlined in BS 8539.

Who is responsible for notifying the relevant stakeholder that the anchor specified has not been supplied?

- BS 8539 highlights the contractor's responsibilities, under clause 10 of the management procedure;

- If the contractor is aware that the anchor specified is not the one supplied on site it is their responsibility to inform the original specifier and once the new anchor has arrived, having gone through the correct due diligence of selecting an anchor, then it should be installed To the manufacturer's specifications.

If an alternative anchor is similar in its description and specification, why can’t we select a different anchor?

- Most anchors have a different manufacturer reference.

- Many anchors have unique performance characteristics

- Most anchors are manufactured differently with specific load characteristics.

- Installation instructions may differ

- Even though visually they look the same, the approvals may differ

According to BS 8539 if you decide to change the anchor then you must follow clause 10 of the management procedure.

How does BS 8539 guide us?

BS 8539 is quite clear “The correct anchor must be sourced as specified. If an alternative anchor is proposed, the change management procedure must be followed”

Clause 10 – management procedure – BS 8539 guidance

Whoever decides to break spec and chooses an alternative anchor becomes the specifier and with that, the responsibility to carry out the management process. The alternative specification should be confirmed by the original anchor specifier who has access to the original design data (via the anchor manufacturer, on-site designer & supplier) The full process must be complete, using the BS 8539 as guidance. Therefore we need to look again at the selection criteria of an anchor as outlined in BS 8539.

BS 8539 anchor selection criteria

When an anchor is originally selected by the specifier, it is the responsibility of the specifier to understand the following selection criteria:

- Substrate – the manufacturer should advise what substrate is suitable for that anchor, cracked, or non-cracked concrete.

- Loadings – what load can the fixing take and can the fixing perform to the load requirement? Once again, this would be outlined by the ETA.

- Environment – is it a corrosive environment?

- Type of install – is it going to be a through fix or a flush fix?

- Type of anchorage – torque-controlled, deformation-controlled, undercut/key or resin.

- Approvals – ETA documentation.

In conclusion, BS 8539 clearly states that you can only replace an originally specified anchor if you change the management procedure.

Are you looking for a single source for the supply, installation training, and testing of anchors?

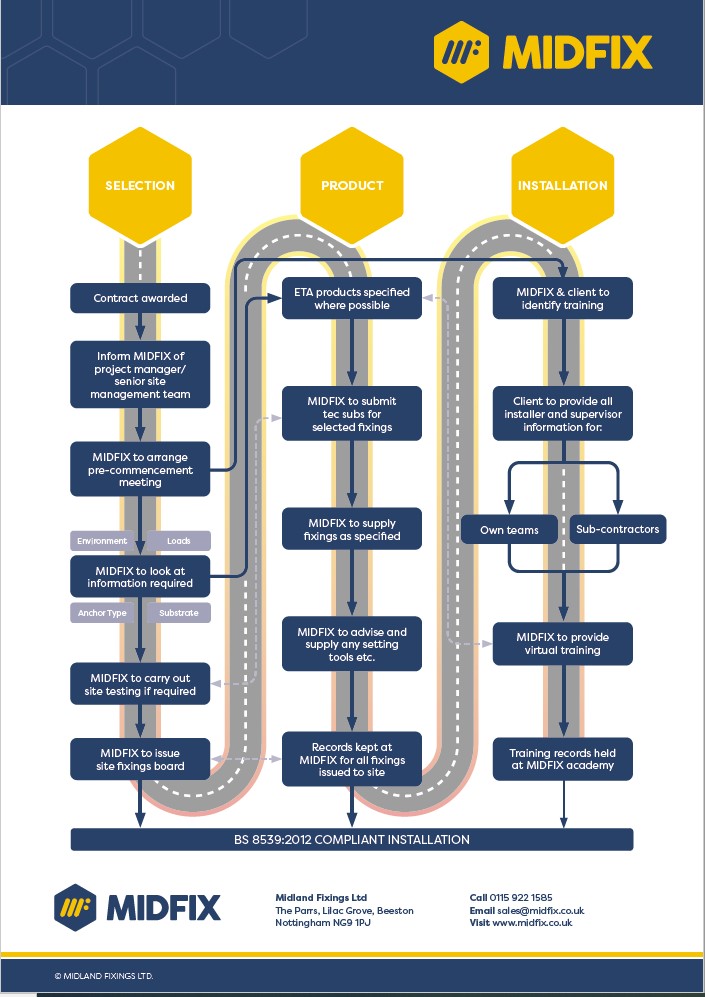

See our simple roadmap below highlighting all of the anchor services we offer in line with BS 8539.

Looking to upskill on-site installers and supervisors?

Join other UK-leading M&E contractors as they put their installers through the MIDFIX Academy’s online training courses.

Start the conversation around anchor/fixing compliance today.

0115 922 1585

sales@midfix.co.uk

Customer services live online Chat – (Monday – Friday 7 am – 5 pm).