As you’re reading this article, I’m assuming you’re probably on the fence about whether you should start adopting anchor installation compliance in your M&E projects.

Maybe you’re wondering, is it worth the effort, time, and money? It’s not law-binding, so is it even really necessary? What difference does it make?

Well, I’ve compiled a brutally honest and objective list of the pros and cons attached to implementing the BS:8539 to help give a better understanding of what really goes into the process. Once you get an idea of the good, bad, and ugly behind the scenes, you can decide for yourself if it’s worth it.

This article will cover:

- Pro #1: Evidence

- Con #1: Change of culture

- Pro #2: Safety

- Con #2: Time

- Pro #3: Reducing rework

- Con #3: Cost

- Pro #4: Avoid reputational damage

- Con #4: Results not immediate

- Pro #5: Upskill your team

- Con #5: Limited supply chain options

- Conclusion

Let's start on a good note...

Pro #1: Evidence

The initial, main motivation behind a compliant anchor installation is to gain the evidence that comes with it. No matter how safely and accurately you’ve installed an anchor, if you’re asked and you don’t have the satisfactory evidence to prove it, all that effort you put in is basically nullified. Often, the aspirations behind compliance are led by Tier 1 contractors, so investing in this would make you seem much more attractive to the ‘big dogs’, and potentially increase your chances of being recommended for other jobs and winning bids; provided you’re able to demonstrate, in the bid phase, that you’ve done your due diligence. If you’ve used a Fixings and Anchors policy, showing this certainly makes a great argument. It assures that the Tier 1s that, should something go wrong, both of you wouldn’t be liable – the manufacturer would have to take accountability because you’ve done everything correctly, so the fault must be in the product.

Con #1: Change of culture

Possibly the most prominent hurdle preventing many from carrying out compliance is having to challenge the mindsets and longstanding practices in the industry. Installers are generally proud, and rightly so, of their workmanship; and suggesting following a British Standard of compliance may be taken offense at or seen as an insult. You’ll often hear: “well, I’ve done it this way for decades and I’ve never had any failures,” or, “I know what I’m doing”, or the likes. Trying to shift this traditionalist perception is not easy – after all, “if it ain’t broke, don’t fix it”, right? The intention isn’t to condemn the way the installations are currently being done, nor the workmanship, but to prove our due diligence in order to ratify them and indicate that the installer has gone through adequate training, and it’s been signed off by the supervisor. The buy-in needs to span across the team – if it’s just the project manager that’s in agreement, but the installers aren’t convinced, then it’s pointless. Understanding the why and how of it is imperative for the change to be effective.

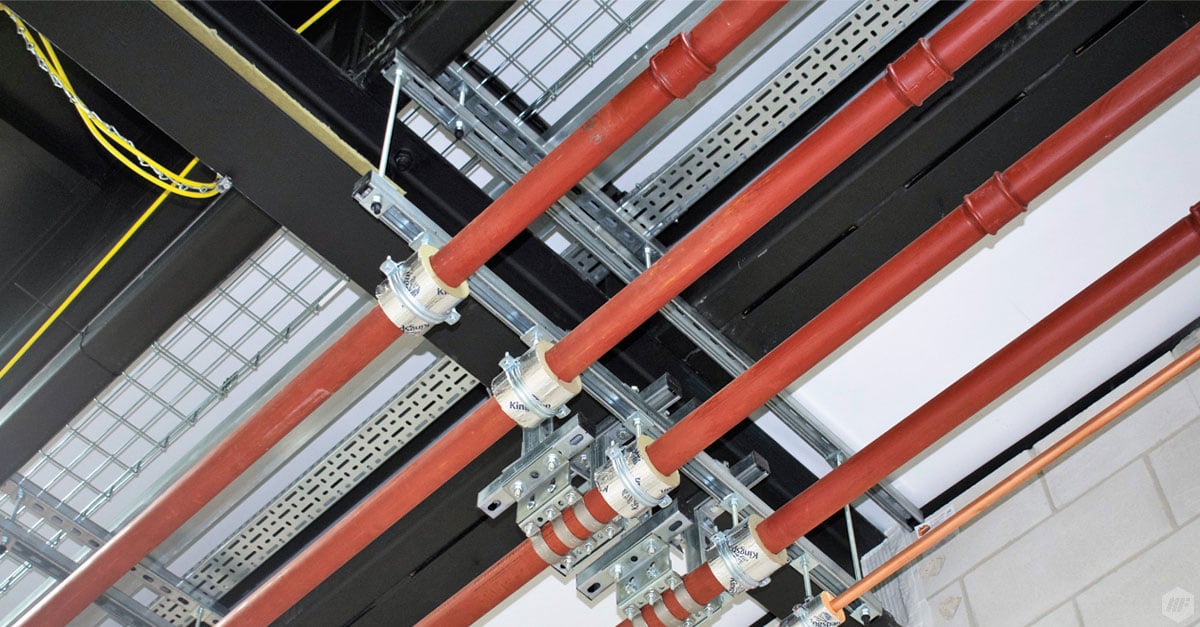

Pro #2: Safety

I’m going to hope this point is self-explanatory. The whole reason for everything I’ve said so far, why you would even be asked for evidence of a compliant anchor installation in the first place, and the purpose of the BS:8539, is to ensure the safe selection and installation of anchors. If the wrong anchor is selected, or the right one is but it’s installed incorrectly, it’s likely to fail, be unable to carry the intended loads, and collapse. This could (and has in the past) cause not only monetary loss, but injury and in extreme cases, death. While you may be confident that you do everything correctly and safely regardless, ethically, you can never be too sure. The idea is to reduce health and safety risks, both in the live site environment but also in the lifespan/ongoing safety of the building post-handover.

Con #2: Time

To make it even worthwhile, you have to be involved with anchor compliance at the start and put in the effort up front. You can’t leave it to the last minute, which means you need to plan ahead more. You’ll have to engage the supply chain and other stakeholders early on to identify the substrate and whether you have all the required information about the substrate i.e. its performance data. This would then be passed onto the relevant stakeholder; for example, the anchor supplier could be the specifier in this case, identifying which anchor is required, so they’d need the substrate information. In cases where this information (performance data) isn’t known, the anchor provider might actually have to go to the site and undergo a test in the substrate to determine which anchor to use. This in itself requires meticulous planning and coordination prior to the process, which obviously could cause further delays, making the entire process take up to 6-8 weeks. Traditionally, things are done much more spontaneously – the anchor needed could be ordered just a day before the installation is scheduled to take place.

Pro #3: Reducing rework

If you make sure you’ve done everything precisely the first time, you’re less likely to have to rework your installations. Oftentimes, anchor compliance is considered only reactively, as opposed to proactively – if you don’t think of the potential mishaps ahead of time, you have no choice but to deal with them when they do arise! In instances where M&E contractors have installed anchors (without following a standard), and then are asked for evidence by the Tier 1 contractors that the installations were compliant, often the entire project is scrapped and redone – back to square one. Ouch. Couldn’t be me. Being compliant from the get-go negates this issue, which also reduces long-term costs. This brings us to my next point...

Con #3: Cost

The upfront costs that come with executing anchor installation compliance can be off-putting. If you’re installing an anchor compliantly, you’d be following the principles of the BS:8539 which state that, if you know the performance capabilities of the substrate, you can specify an ETA (European Technical Assessment)-approved anchor which doesn’t require testing. On average, a box of 100 ETA-approved anchors tends to be around 55% more than a box of wedge anchors without an ETA approval. If you specify a non-ETA anchor, you can still do so in a compliant way: by undergoing extensive testing of said anchor. That would understandably consume some time, however, and time = money, as we all know! Seriously, though – as previously mentioned, being compliant will take up much time, which means more labour and man-hours, which means extra short-term costs. Moreover, the BS:8539 emphasizes the importance of having a supervisor on site and signing off the project; a step that wasn’t there beforehand. Supervisors have to be trained, and so do the installers. Of course, training them would mean investing time as well as money, so this adds to the costs. The CFA (Construction Fixings Association) Supervisor courses usually cost £300 in total - it's an investment, but a necessary one. However, you don't have to spend to train for installation. MIDFIX offers a free 'Competent Anchor Installer' course here.

Pro #4: Avoid reputational damage

Even though standards are not legally binding, not following a code of practice and being compliant would class you as negligent. If something does fail or go wrong, and you can’t verify that it wasn’t due to an incompliant installation, that could have a far-reaching impact on your organisational reputation in the marketplace, and your ability to secure future projects. The other side is that the M&E sector is slowly but surely moving towards this direction of a more compliant and responsible future; so those that don’t take it up may have a stain on their reputation permanently. Instead of being set in your ways, adopting this early gives you the opportunity to get ahead of that.

Con #4: Results not immediate

I suppose a drawback to compliant installations is the fact that the results are usually invisible – so you can’t always tell whether a difference was made. For example, if we take a through-bolt, the installer training teaches that you have to make sure the hole is cleaned correctly when installing one. This could be something that you haven’t done before – however, the difference can’t be seen visually because it’s below the surface of the substrate. Technically, it could even be installed incorrectly and you could still get away with it. Usually, when someone has invested time, money, and effort into something, they like to be able to see physical or tangible results i.e. return on investment; which is fair enough. So, when the results can’t be seen, it can be somewhat discouraging, prompting the question “what was the point?” from those who invested the time and effort i.e. installers. Well, the point is to know in your heart that it was done correctly and in good faith! Just kidding. But not completely. There’s no other way to ensure safety without taking all the measures to be compliant. Maybe you didn’t even have to do anything different from how you normally do it, but the point is you now have the data to back it up. The impact is definitely there, but more likely to be noticed further down the chain as opposed to immediately.

Pro #5: Upskill your team

All in all, taking the BS:8539 into account and acting accordingly gives your team the opportunity to enhance their skill sets and work on their personal development, boosting team morale along the way. These are skills that will be beneficial for you in the long run and that will stick with you for life. You also gain a qualification in the process, as there are training courses out there that come with certificates.

Con #5: Limited supply chain options

Not all anchor distributors have anchor compliance and the BS:8539 principles as a focus of their route-to-market. Some are only interested in the commercial aspect of shifting anchors, which limits the number of people you can source anchors from if you do act compliantly. Moreover, if you are looking to source from somebody who is diligent i.e. go through adequate testing (pull tests), write anchor policies, provide training, etc., the options you can go to for these are limited since a big chunk of the supply chain are mainly concerned with commercial value. To add, if you aren’t following a policy, there isn’t an anchor specification that you have to go with and you’re free to choose. If you are, then you’re obligated to install the anchor specified. In the event that you run into supply difficulties, which is possible due to volatility in the marketplace, steel availability, etc., you’ll have to ‘break spec’ i.e. break away from the selected anchor. To do so, you must follow the change management procedure (under Clause 10), meaning you need to go back and do the selection process all over again which would cause delays.

Conclusion

At the end of the day, only you can decide whether or not you implement the BS:8539 and anchor compliance principles to your installations and projects. It’s also only you who will reap the rewards that come with it if you decide to do so, and who’ll have to bear the consequences if you don’t. Whether you believe in traditional methods and staying put, or adapting in line with changes in the sectors, hopefully, this article has given you enough indication to help you weigh out the pros and cons and decide what your future steps will be.