In the construction industry, the shift towards more sustainable and efficient practices has become a prerequisite for many large government projects. Amid this shift, QMEXX Pipe Supports have emerged to redefine what it means to be sustainable in an industry often criticised for its environmental footprint. With a keen focus on innovation, efficiency, and durability, QMEXX is leading the charge towards a greener future, proving that practical solutions can indeed align with sustainable goals.

This article explores the multifaceted ways in which QMEXX Pipe Supports are setting new benchmarks in sustainability, outpacing traditional fabricated supports through environmental benefits, economic efficiency, and a commitment to reducing resource consumption.

- Why care about sustainability?

- The Limitations with Traditional Pipe Supports

- Introducing QMEXX Pipe Supports

- Production Stage

- Installation Stage

- Reusability

- Longevity and Durability

- Conclusion

Why care about sustainability?

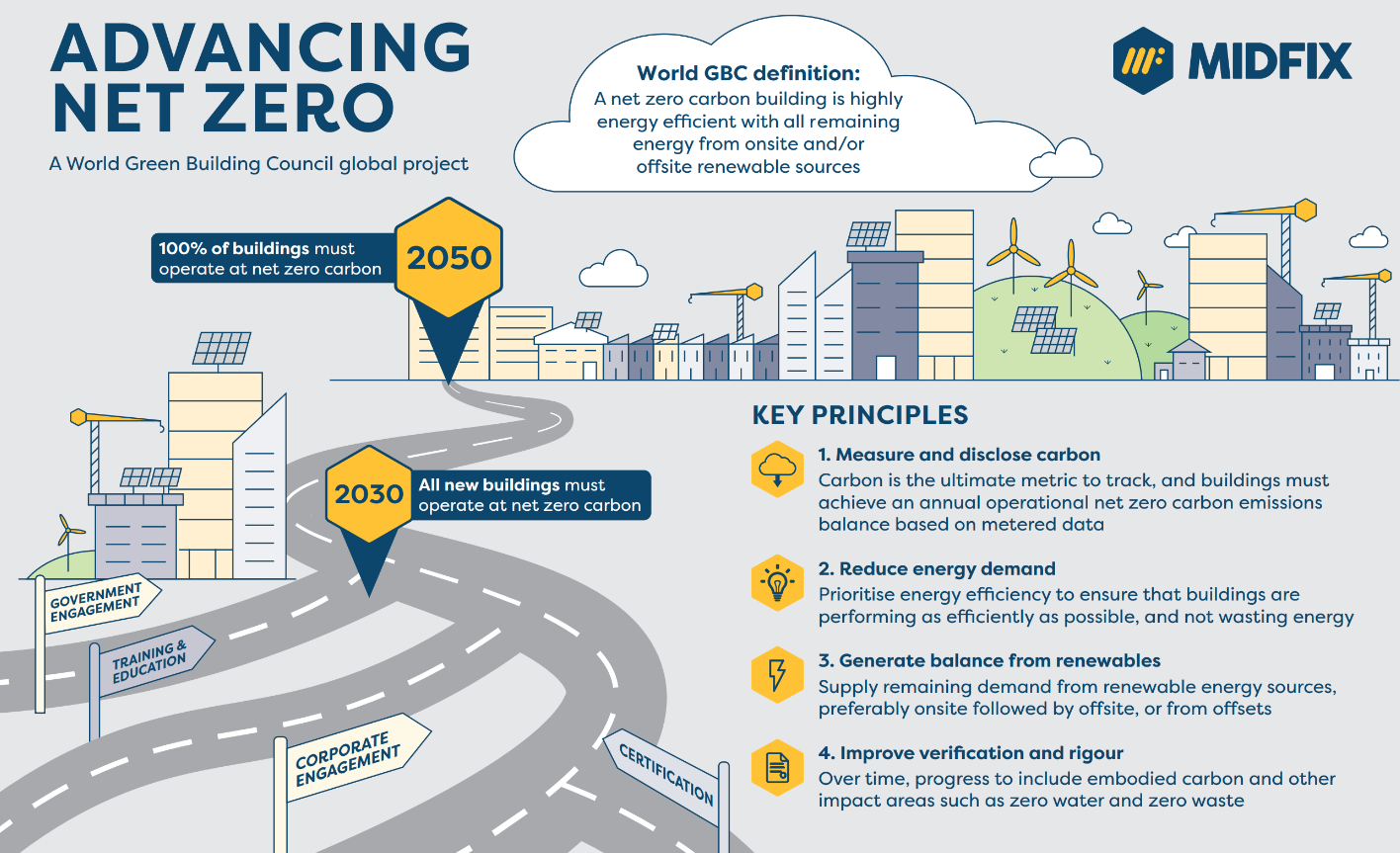

With the approaching target of Net Zero 2050, the significance of sustainability is escalating within the building services supply chain. Contractors vying for major government projects are now mandated to integrate carbon reduction plans into their proposals.

An emerging necessity for Tier 1 contractors is the provision of Environmental Product Declarations (EPDs), which entail disclosing environmental data concerning construction projects.

Among the various aspects covered in EPDs, a crucial one is assessing the 'embodied carbon' of construction projects. This involves meticulously tracking greenhouse gas emissions throughout a project lifecycle, including manufacturing, transportation of materials, construction processes, and a comprehensive lifecycle assessment.

Consequently, Tier 1 contractors are now extending their scrutiny to M&E contractors, ensuring their adherence to sustainability benchmarks. Consequently, for M&E contractors aiming to appeal to these higher-tier stakeholders, demonstrating not just safety and compliance but also environmental consciousness is becoming more and more crucial.

Therefore, even if sustainability isn't your personal priority, the likelihood is that your Tier 1 contractors are prioritising it.

While this may seem like a daunting prospect, there's a silver lining. Utilising QMEXX not only ensures safer and compliant installations but also aligns with sustainability objectives. In essence, it’s a win-win solution.

The Limitations with Traditional Pipe Supports

A challenge that is faced with installing above-ground pipe supports is that oftentimes, the actual on-site measurements differ from the initial site drawings. This is because site drawings do not account for the dynamic and evolving nature of construction sites. Here are some reasons why site drawings can fall short:

- Site Conditions: The conditions on the ground can differ significantly from what is portrayed in the drawings. Unexpected obstacles, variations in terrain, or hidden utilities can all impact the feasibility of adhering to the initial plans.

- Change Orders: Construction projects are prone to changes and modifications, commonly known as change orders. These alterations may involve shifting the location of pipes, adding new elements, or adjusting existing structures. Such changes are often implemented on-site, and it can be challenging to update the original drawings promptly.

- Human Error: Despite best efforts, errors can occur during the drafting of site drawings. Misinterpretations, omissions, or inaccuracies can all lead to discrepancies between the drawings and the actual site.

- Timing: Drawings are typically created in the early stages of a project, often before the site is fully prepared for construction. As the site evolves, what seemed feasible on paper may encounter practical challenges.

This means that many times, traditional fabricated pipe support supports often arrive on-site and fail to meet the specific needs of the site. However, not only is this process expensive, time-consuming and leads to project inefficiencies – it also contributes massively to the carbon footprint of the project. This is how:

- Waste Production: Fabrication processes can generate substantial material waste, including metal offcuts, welding consumables, and other materials. Materials cut or shaped on-site are often tailored to specific requirements, and are less likely to be reused or recycled for other purposes. This limitation can lead to increased demand for new materials, further exacerbating resource depletion and environmental degradation. This waste contributes to landfill growth and increases the environmental footprint of construction projects.

- High Resource Consumption: On-site fabrication often requires the transport of raw materials and machinery to the job site, leading to increased fuel consumption and carbon emissions. This process also demands significant amounts of energy for tools and equipment used in cutting, welding, and assembling materials.

- Emissions and Pollution: Activities such as welding and cutting emit harmful pollutants and chemical gases, contributing to air quality issues and climate change. These emissions can harm both the environment and the health of workers and nearby communities. The machinery and tools used in on-site fabrication can generate high levels of noise pollution, which can pose as another hazard.

Recognising the unsustainability and danger of on-site fabrication, and the fact that it can be significant hindrance to construction work and can lead to project delays, most contractors opt to send traditional pipe supports back off-site for alterations and modifications.

While off-site fabrication offers several advantages in terms of efficiency and quality control for many construction projects, it still leads to unnecessary and avoidable consumption of resources and the generation of material waste.

- Transportation: Off-site fabrication requires products, or large components, to be transported to and from the construction site. This transportation can significantly increase the carbon footprint of a project due to the emissions associated with moving goods over potentially long distances. Additionally, the need for heavy-duty transport vehicles, which are often less fuel-efficient, exacerbates this issue.

- Waste Generation: Hot works such as cutting and welding, regardless of being done on-site or off-site also lead to materials being used inefficiently or discarded unnecessarily. With off-site fabrication, there is also a greater chance of the production of incorrect specifications due to communication errors or last-minute design changes, which means that there is a chance that the pipe supports do not accommodate the changes on-site even after re-modification, thereby prolonging waste generation and material consumption.

So, what is the solution?

Introducing QMEXX Pipe Supports

QMEXX represents an innovative modular pipe support system, featuring a streamlined selection of components that seamlessly integrate with the Sikla Framo modular support systems. This integration facilitates the creation of custom, ready-to-use pipe support solutions, capable of accommodating an extensive array of configurations.

Developed by MIDFIX to address the specific challenges of managing above-ground pipework in the water and utilities sectors, QMEXX brings together a suite of pioneering components. Designed for versatility, QMEXX supports can be easily adjusted or modified on-site to meet any unforeseen changes or discrepancies from the original plans. Eliminating the need for hot works in its manufacturing process and featuring a hot-dip-galvanised finish, QMEXX stands out as a bolt-on solution that ensures both efficiency and longevity in pipe support.

However, the advantages of QMEXX don’t just stop there. Its design and functionality are committed to ensuring environmental sustainability in every stage of its lifecycle, from production through installation to long-term use. This is how:

Production Stage

QMEXX is prefabricated using readily available “off-the-shelf” components that can be designed bespoke to meet your site’s needs. These components allow for rapid assembly directly on the construction site or can be delivered pre-assembled for immediate use.

Pre-fabrication means QMEXX components are manufactured in a controlled environment, optimising material use and minimising waste. This process ensures that each piece is produced with precision, reducing the excess materials often generated through on-site fabrication. It also lowers the need for transporting multiple materials and tools to the site for on-site fabrication, as QMEXX is designed to be compact and easily transportable, optimising logistics and cutting down on carbon emissions. The controlled setting also allows for more energy-efficient manufacturing practices, as energy use can be closely monitored and minimised, further enhancing the sustainability of the production phase.

Fabricating components off-site in a controlled environment can reduce the potential for accidents and injuries compared to traditional on-site construction activities.

Installation Stage

The adjustability of QMEXX Pipe Supports is a game-changer for sustainability in construction. Thanks to its innovative multi-holed box section design, assembling a wide range of pipe supports, including post brackets, goal posts, cantilever brackets, and gantries, can be accomplished within minutes, all with the convenience of a single fastener. This feature allows for on-the-fly modifications to accommodate any unexpected site-specific conditions without the need for hot works, additional materials and custom measurements.

From a sustainability point of view, this offers several advantages:

- Reduces Transportation Emissions: Minimises the need to transport supports back to the factory for re-fabrication off-site, lowering carbon emissions associated with transportation.

- Minimises material waste: The adjustability of QMEXX means that there is no need for corrective fabrication. This philosophy optimises the use of materials and minimises the unnecessary waste generated from offcuts and excess scrap material that are discarded for not fitting the project’s evolving needs.

- Energy Conservation: The elimination of energy-intensive modification processes (like welding and cutting) leads to overall lower energy that would otherwise be used in powering welding equipment and cutting tools.

- Workplace Safety: Hot works, such as welding and cutting are labour-intensive and pose significant safety risks, including toxic emissions and energy-intensive processes. QMEXX's design eliminates the need for such procedures with its adjustable and easy to install design, enhancing worker safety and reducing harmful emissions both during assembly, and in the future.

In essence, QMEXX pipe supports embody sustainable construction principles by optimising material use, minimising waste, and reducing energy consumption during its production and installation stage. However, the sustainability movement in construction does not just stop at manufacturing, but also concerns a lifecycle assessment of the environmental implications of your products. The following sections elaborate on how QMEXX Pipe Supports are not merely a product but a sustainable solution extending beyond initial use.

.jpg?width=3648&height=2736&name=P1110604%20(1).jpg)

Reusability

QMEXX Pipe Supports are designed with sustainability at their core, emphasising not just efficiency and adaptability in their initial installation but also in their potential for being dismantled and reused. This feature significantly enhances their sustainability credentials in several ways:

- Flexibility in Application: The modular design of QMEXX Supports means they can be adapted to new requirements with minimal effort. This flexibility allows for the supports to be reused in different configurations or applications, extending their lifecycle and reducing the environmental impact associated with producing new supports.

- Design for Disassembly: QMEXX Pipe Supports are engineered to be easily dismantled without compromising the integrity of the components. This design philosophy ensures that when the supports are no longer needed in their current configuration, they can be disassembled quickly and without damage.

- Reuse and Repurposing: Once dismantled, the components of QMEXX Pipe Supports can be repurposed or reused in other projects. This ability to reuse materials helps reduce the demand for new raw materials, conserves resources, minimises waste, aligning with circular economy principles.

- Cost and Energy Efficiency: The reuse of QMEXX Pipe Supports not only saves on the cost of materials for new projects but also reduces the energy consumption associated with manufacturing new components. This efficiency contributes to a lower carbon footprint for construction projects.

- Reduction in Waste: By facilitating the dismantling and reuse of pipe supports, QMEXX significantly contributes to waste reduction. Traditional pipe supports might end up in landfill at the end of their service life, whereas QMEXX supports can be reused, thus minimising waste.

The ability to dismantle and reuse QMEXX Pipe Supports embodies sustainable construction practices by promoting longevity, reducing waste, and conserving resources. The adaptability of QMEXX supports encourages a shift away from the traditional 'take-make-dispose' model towards a more sustainable model that values the longevity and versatility of materials.

Longevity and Durability

QMEXX Pipe Supports have been subjected to comprehensive testing protocols and therefore come with loading data to validate their strength, durability, and resilience under various conditions. These reports offer detailed insights into the structural integrity and load-bearing capacity of QMEXX components, with each part undergoing rigorous testing and analysis, both at an individual level and as a system. This data-backed approach instils confidence in the system's ability to exceed industry safety standards. The design is such that the supports can be reconfigured into a wide range of pipe supports to meet varying needs for varying projects without causing material degradation. Additionally, the hot-dip galvanised finish ensures that the material is protected from corrosive environments common in wastewater recycling facilities.

Furthermore, QMEXX's extensive usage in over 500 projects serves as a powerful testament to its reliability and adaptability across a diverse spectrum of applications. This real-world validation not only showcases the system's theoretical safety but also demonstrates its proven performance in practical, on-site conditions.

The durability and tested reliability of QMEXX Pipe Supports translate directly into fewer needs for reworks and maintenance. Traditional supports, prone to wear and tear, often require frequent inspections and replacements, contributing to higher resource consumption, labour and increased waste over time.

In contrast, QMEXX's longevity means that once installed, the supports remain functional and dependable without the constant need for intervention. This stability significantly diminishes the environmental toll associated with manufacturing replacement parts, transporting materials, discarding worn materials and components, and the energy and labour consumed during these activities.

Conclusion

QMEXX transcends conventional sustainability practices by embedding eco-consciousness not only during production and installation but also throughout its lifecycle, epitomising the principles of the circular economy. This commitment extends beyond the immediate benefits, aligning with the principles of the circular economy by ensuring that the supports can be adapted, reconfigured, and reused across multiple projects and applications. The inherent durability of QMEXX products means they stand the test of time, reducing the need for replacements and thus minimising waste and resource consumption. By designing supports that can easily be adjusted to meet evolving project needs without compromising on performance or reliability, QMEXX contributes to a sustainable construction ecosystem that values resource efficiency, waste reduction, and the longevity of materials. In doing so, QMEXX not only adheres to sustainable practices but also sets a benchmark in the construction industry for integrating the ideals of the circular economy into every aspect of its operations, from production through to the end of product life, fostering a more sustainable and environmentally responsible future.