The construction industry is dealing with a changing landscape.

And it’s no surprise, considering the Net Zero goal for 2050 and how many unsustainable and inefficient practices have remained the same for decades.

It’s about time for us to adjust, adapt, and optimise.

The best way to do that is by implementing Modern Methods of Construction.

Not only would this make a sizeable positive impact on the environment, but it would also enable you, as an M&E contractor, to get the most out of your projects.

This article will cover:

- What is MMC?

- Why is there a need for MMC?

- How will MMC solve these problems?

- What is being done to help facilitate the adoption of MMC / offsite construction?

- What is the Offsite Alliance?

- How can the Construction Innovation Hub help?

- What is the Carbon Reduction Plan?

- Conclusion

Intrigued? Keep reading!

What is MMC?

MMC stands for modern methods of construction and refers to non-traditional methods of building new homes. This normally entails manufacturing the units off-site and subsequently assembling them together on-site.

The UK government started an initiative to facilitate MMC adoption and as part of that, the CEO of Cast Consultancy, Mark Farmer formed a workgroup to come up with a definition framework of MMC.

(Modern Methods of Construction - clearly defined the term)

Farmer is the CEO of Cast, a specialist construction consultancy which provides solutions for developers, investors, and policymakers in the supply chain. They’ve done lots of work with the governments consulting on offsite construction, an example of which being the ‘Modernise or Die: The Farmer Review of The UK Construction Labour Model’ that Farmer undertook.

The framework now breaks up MMC into seven different categories, with two of them being site-based process improvements. Let’s look at what they are.

- Category 1: Pre-manufacturing (3D primary structural systems)

- Category 2: Pre-Manufacturing (2D primary structural sy1stems)

- Category 3: Pre-Manufacturing components (Non-systemised primary structure)

- Category 4: Pre-Manufacturing - Additive Manufacturing (structural & non-structural)

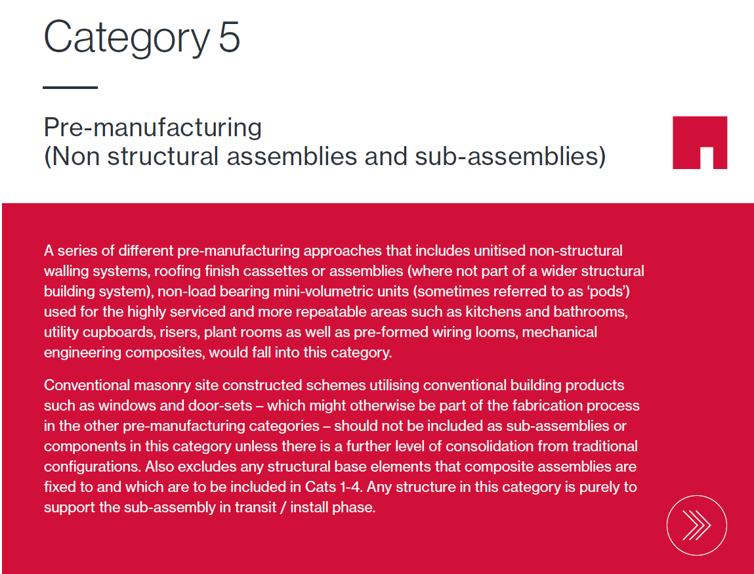

- Category 5: Pre-Manufacturing – (Non-structural assemblies and sub-assemblies)

- Category 6: Traditional building product-led site labour reduction/productivity improvements

- Category 7: Site process-led labour reduction/productivity/assurance improvements

The category that M&E contractors should be concerned with is Category 5.

Why is there a need for MMC?

At this point, it shouldn’t come as a surprise that we’re dealing with a changing landscape in the M&E sector and the construction industry as a whole. We’re seeing incremental changes and new regulations and policies emerging, in hopes of paving the way for a safer built environment and working practices.

The tragedy of the 2017 fire in Grenfell tower was a construction failure of a huge scale, and it instigated this newfound movement for compliance & safety, for good reason. As a result, in contrast to the predominantly reactive approach in our sector, we’re now seeking a more proactive approach, trying to make changes for the better.

The first and most impactful example is the 2018 report by Dame Judith Hackitt; this also gave rise to the proposal of The Building Safety Bill, which turned into an Act after receiving Royal Assent in April this year. These emphasise the lack of provability and traceability in the industry and the need for a larger focus on these in order to achieve safer buildings.

Hackitt recommended the introduction of a ‘golden thread’ i.e. “the information that allows you to understand a building and the steps needed to keep both the building and the people safe, now and in the future”, as defined by the Building Regulations Advisory Committee.

Off the back of that, duty-holders will be required to maintain comprehensive records of information for higher-risk buildings, including how they’re constructed, how safety is designed into them, how they will be maintained, etc. All of this could come into effect as early as April 2023; so be prepared!

Prior to that, the aforementioned ‘Modernise or Die’ report was published in 2016 and highlighted key shortcomings in the UK construction industry and the need to evolve. Two years later, the House Of Lords held a Select Committee (Science and Technology Select Committee - Off-site manufacture for construction: Building for change) which generated some buzz around this topic.

The report and the Committee centred around labour, as there is now a huge skills shortage in construction, which was exacerbated by the COVID-19 pandemic, and on how the manufacturing sector can utilise MMC to plug the skills gap even.

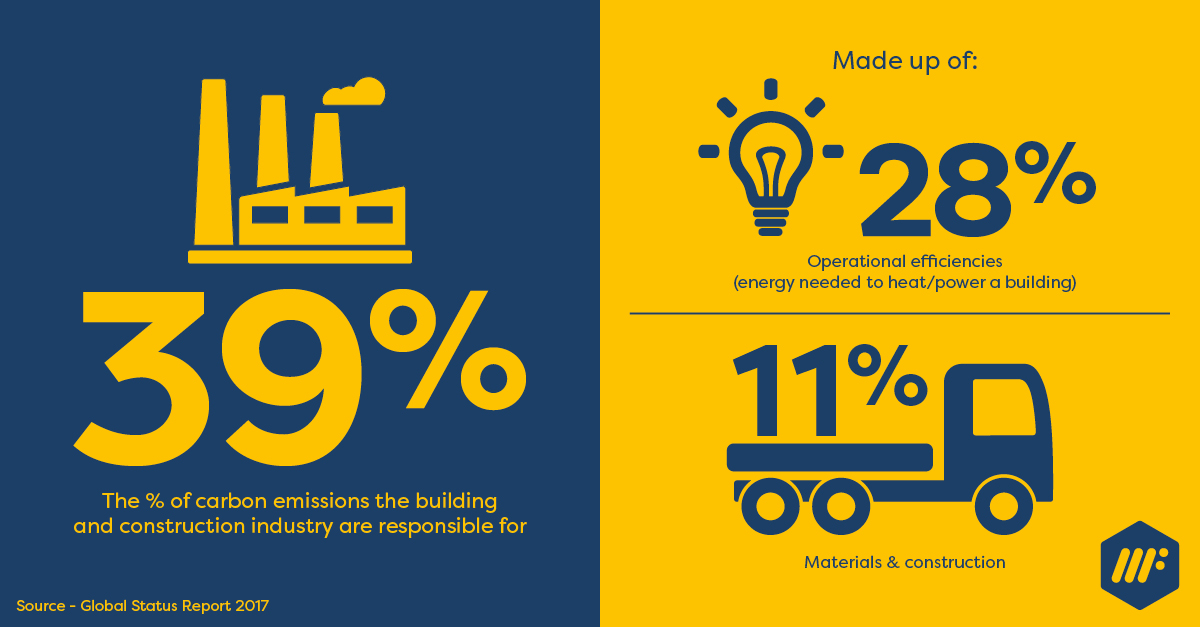

Not to mention how MMC fits with the Net Zero 2050 goal of reducing carbon emissions to zero! Recent studies have found that offsite construction emits a whopping 45% less carbon than traditional methods of construction (HTA Citation). I don’t know about you, but I feel like this isn’t getting the attention it deserves!

Considering that the building and construction industry is responsible for 39% of ALL carbon emissions (Global Status Report, 2017), reducing those by almost half would make a significant difference.

In short, there are many goals in mind for the industry, and MMC aligns with and assists in achieving all of them.

How will MMC solve these problems / help you win more projects?

The construction industry doesn’t do revolution – it does evolution. Meaning, you can never change everything all at once on one momentous occasion, but you can make gradual incremental changes over time; and MMC is an example of this. The idea has been around for a while now, but it’s slowly evolving into the industry.

With MMC, and in particular offsite construction, you have a lot fewer variables to think about when compared to on-site construction. As mentioned, it would help to plug the skills gap as it requires fewer people on site and takes the skills responsibility away from the site environment and into the manufacturing environment, where it can be controlled much better from a process point of view.

For example, welding is a specialist skill that’s required when adjusting traditional steel supports on site. In a factory-controlled environment, the risks of failures, falls, and injuries are substantially reduced. This also means you’re much more likely to get the project right the first time, and that you won’t need to spend any money on costly rework.

Plus, efficiency and quality control are considerably improved with offsite. Offsite assemblies would be thoroughly checked before despatch, ensuring consistency, and the frames would be supplied to site already labelled, and ready for installation. This means you’ll save a great deal of time, whilst also ensuring your projects are much more likely to be delivered on time.

At the same time, thanks to the prior analysis and preparation that goes into offsite construction, the structures follow best practices making them safer and longer-lasting. If you adopt the MMC mindset, you’d be involved much earlier in the process and therefore afforded the time to consider much more in terms of compliance and information to hand over, making you much more attractive to Tier 1 contractors who are now requesting evidence of such things.

In fact, according to research done by the NHBC Foundation and Cast Consultancy, there is ‘...the potential for a 30% improvement in the speed of construction of new homes through the adoption of innovation, with a potential 25% reduction in costs, as well as the potential for advances in improving quality and energy efficiency.’(1)

To boot, prefabrication eliminates waste of materials such as channel, as you would only cut off exactly the amount that you need. That, combined with the increased efficiency, cutting time, and less remedial work, also means less costs overall. Win-win!

The same is true when it comes to sustainability. When taking it offsite, your manufacturing process is much more optimised, so you’re using much less energy (45% less carbon) than you would on site, and that links with the sector’s environmental goals.

It plays into many things that are coming out in terms of policy and best practice guidance, including the Golden thread, the Building Safety Act, the Construction Playbook, the Net Zero 2050 goal, and more, which all point to words MMC and offsite helping to solve problems in our industry. For you, an M&E contractor, proving that you are implementing practices with these goals in mind will set you apart from others.

What is being done to help facilitate the adoption of MMC / offsite construction?

In 2019, the Offsite Alliance was formed to encourage the industry to speed up the process of adopting MMC and making offsite the go-to method of manufacturing, born out of the clear need for more affordable and sustainable homes.

It works alongside leading industry bodies and organisations, and aims to break down barriers setting us back; one of which is the resistance to collaboration between contractors as this can be seen as competition, when in reality, working together to implement off site would prove beneficial for all parties.

What is the Offsite Alliance?

The Offsite Alliance were given £75 million in investment to spend over a four-year program on research & development for integrating offsite & prefabrication into construction. Since then, they have hosted a number of seminars and panels, including some during the UK construction week.

One of the Offsite Alliance panellists at the event mentioned that “traditional construction has plateaued and will probably worsen with the skill shortage”, and that “there’s a greater need to document the success of offsite to educate more”, hence their mission.

Moreover, a term that came up often was ‘value-based decisions’, establishing that the long-term value of decisions needs to be at the forefront as opposed to the current traditional method of only looking at short-term results and initial cost reduction. Akin to the shift from being reactive to proactive, the aim is to move our attention from immediate/instant gratification (without consideration of long-term effects) to better long-term value and future rewards.

How can the Construction Innovation Hub help?

The Offsite Alliance work in partnership with the Construction Innovation Hub, which was set up by the government and funded by UK Research & Innovation to assist with this industry-wide transformation. They created a framework called the Value Toolkit as part of this; it is a set of tools to encourage clients & policymakers to make value-based procurement decisions that will lead to the desired environmental, social, and economic outcomes.

“There's been too much emphasis historically on just looking at 'lowest cost wins'. If we try and buy cheap, then we're not delivering value; we're not delivering that economic growth that can come from that investment. It's all about, in our view, raising awareness of the benefits of looking at a project in a much wider perspective than just cost”

- Steven Thompson, Senior Specialist - Construction Standards Royal Institution of

Chartered Surveyors (RICS)

When looking at a building, we should no longer just focus on the building during the construction phase, but its overall life as well, and the Toolkit allows you to do that. MMC aligns with this as it lengthens the lifespan of a building, therefore adding to its whole-life value.

Coupled with this, we also often hear the phrase ‘Pre-Manufactured Value’ (PMV), which can be defined as the “% percentage measure of offsite construction used on a project” (Designing Buildings Wiki, 2021). As the demand for sustainable building practices increases alongside the drive to deliver projects under tight deadlines, principal contractors may keep an eye on the PMV of your projects. Do with that what you will! But this value is of importance because:

- It improves the predictability of a project’s outcome

- There is a clear improvement in productivity and waste reduction

- There are quality and performance improvements (including operational carbon)

- A decreased health and safety risk

What is the carbon reduction plan?

In relation to the Net Zero goal, contractors bidding for large government contracts over £5 million must now outline how they plan to reduce their embedded and operational carbon by 2050 through a carbon reduction plan (CRP). If not, they will not be considered – so you could be missing out on some big projects if you don’t turn to MMC. This is part of a Guidance Note from the government titled ‘Promoting Net Zero Carbon and Sustainability in Construction’, which can be found here.

Conclusion

There are also aspirations from the public sector and government to have a more standardised approach, and with MMC, that’s possible. While there’s always a bespoke element to offsite manufacturing, there are certain types of buildings that are better suited to standardisation of sub-assemblies. Those buildings would be ones which are quite repeatable in design and style, such as prisons, hospitals, public buildings, etc., and can be easily manufactured in an almost identical manner, significantly cutting time and costs.

Needless to say, it is definitely collectively agreed that MMC and off-site construction is the way to go, even being called the ‘future of construction. Things are happening – so, get ready!

References

- Shilton, E. (2021) What Are Modern Methods Of Construction? Legal & General. Source: https://www.legalandgeneral.com/adviser/mortgage-club/news-and-insights/digest/articles/what-are-modern-methods-of-construction/#:~:text=Modern%20methods%20of%20construction%20(MMC,putting%20them%20together%20on%2Dsite

- HTA, (2020). ‘Life Cycle Assessments of The Valentine’, Gants Hill, UK and George Street, Croydon, UK. Source: https://www.hta.co.uk/project/Valentine

- World Green Building Council, (2019). ‘Bringing embodied carbon upfront’. Source: [https://worldgbc.org/advancing-net-zero/embodied-carbon/]

- Government Commercial Function, (2022). Promoting Net Zero Carbon and Sustainability in Construction Guidance Note. Source: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1102389/20220901-Carbon-Net-Zero-Guidance-Note.pdf’

- NHBC Foundation (2018). ‘Modern Methods of Construction - Who’s doing what?’. Source: [https://www.nhbcfoundation.org/wp-content/uploads/2018/11/NF82.pdf]