In the water and utility industry, the choice of above-ground pipe support systems plays a significant role in project success. As the demand for innovative solutions rises, the industry is witnessing a transformative shift from traditional fabrication methods to modular alternatives like QMEXX. In this era of evolving technologies and heightened cost-consciousness, it becomes important to scrutinize the options available and weigh the benefits against the expenses.

In this article, we will conduct a thorough cost-benefit analysis to dissect the merits of QMEXX in comparison to traditional fabrication methods. As we delve into this cost-benefit analysis, we will look at not only the upfront costs, but the installation timelines, adaptability and safety to determine the long-term implications for projects in the water and utility sector.

Traditional Fabrication Methods

Traditional fabrication methods have long been the go-to approach for above-ground pipe supports. Typically involving on-site measurements or referencing site drawings, these methods often fall short due to discrepancies between initial designs and the rugged reality of outdoor environments. Welded fabrications, while sturdy, face challenges in modifying on-site, leading to project delays, increased costs, and compromises in safety.

QMEXX Modular Pipe Support System

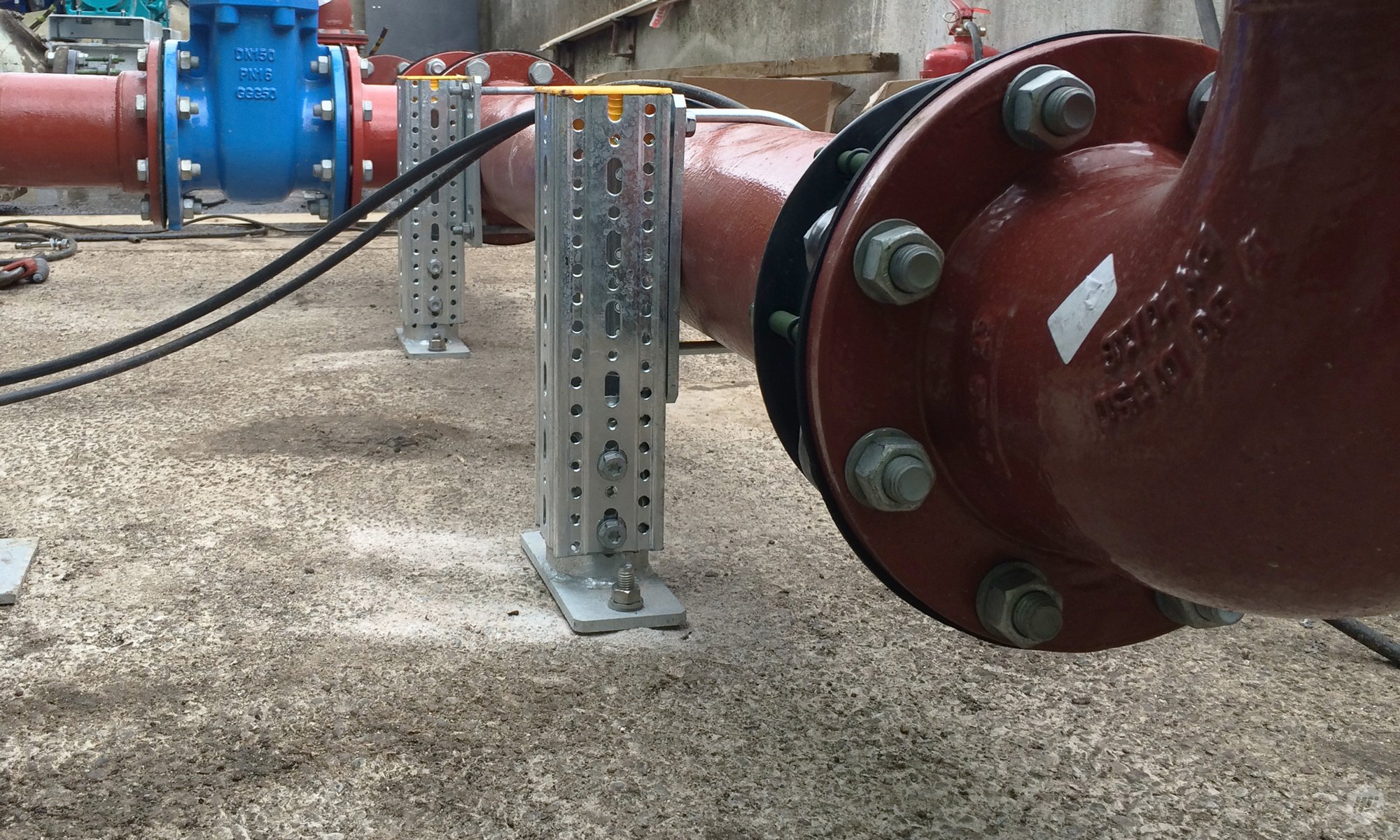

On the flip side, QMEXX is a modular pipe support system that consists of a simple range of components that integrate with the Sikla Framo modular support systems to create a bespoke, off-the-shelf pipe support systems offering almost unlimited variations.

Crafted by MIDFIX, QMEXX is a unique assembly of pipe support components designed to combat above-ground pipework challenges faced by the water and utilities industries. Comprising a range of innovative elements, QMEXX can be swiftly assembled on-site or supplied pre-assembled, offering instant adjustment and adaptation to accommodate changes and variations from initial drawings. With no hot works manufacturing required and a hot-dip-galvanized finish, QMEXX emerges as a bolt-on solution that promises efficiency and durability.

Still not convinced? Let’s do a more in-depth comparison of QMEXX and traditional fabrication by looking at the following key areas:

- Traditional Fabrication Methods

- QMEXX Modular Pipe Support System

- Upfront Costs Comparison

- Installation Time and Labour

- Adaptability

- Safety Considerations

- Environmental Impact

- Long-Term Cost Savings

Upfront Costs Comparison

When embarking on a project, one of the primary considerations is the upfront cost involved in implementing a pipe support system.

Traditional fabrication methods, while often featuring a cheaper cost of material, come with a trade-off. While initial material costs may be lower, traditional fabrication methods often demand on-site customization and welding, contributing to higher upfront costs. The potential reliance on specialized third-party fabrication companies and need for modifications off-site can lead to increased expenses, labour times and project delays. The traditional approach may also incur additional expenses related to the unpredictable nature of site conditions, alterations, and the need for temporary supports during the modification process.

Meanwhile, while the material costs of QMEXX may appear to be slightly more, the added benefits it brings by being “bespoke off-the-shelf” and easily modifiable significantly bring down costs. The modular design enables off-the-shelf availability and adaptability, eliminating the need for extensive on-site fabrication, thereby reducing costs associated with specialized labour and equipment. The absence of hot works or welding further contributes to the cost-effectiveness of QMEXX. Additionally, the ability to easily assemble components on-site or opt for pre-assembled solutions adds flexibility without sacrificing affordability.

Installation Time and Labour

Time is of the essence in project execution, and the efficiency of the chosen pipe support system can significantly impact installation timelines and, consequently, overall project schedules.

Traditional fabrication methods often entail a prolonged installation process. Waiting for supports to be modified off-site can lead to project delays, impacting timelines and potentially incurring additional costs. The heavyweight nature of traditional fabrications also poses challenges in handling and manoeuvring on-site, contributing to increased labour hours.

QMEXX excels in reducing installation time and effort. Supports of any type and size with structural performance can be made from off-the-shelf components, contributing to pipe supports that are fully galvanised, installation-ready, and available for next-day delivery. Due to the multi-holed box section design, you can assemble a full range of pipe supports including post brackets, goal posts, cantilever brackets and gantries within minutes, and that too, with a single fastener! Therefore, contractors can bypass the waiting period associated with traditional supports being modified off-site. Supports can also be easily modified on-site, preventing the need for costly and time-consuming reworks.

With QMEXX components weighing up to 80% less than their traditional counterparts, handling and installing them becomes a more streamlined process requiring less labour on-site.

Adaptability

When it comes to wastewater recycling facilities and utilities sites, site conditions and terrain can vary quite dramatically. For instance, ground elevations can be inconsistent, affecting the levels at which concrete plinths are placed. This means that oftentimes, the site drawings don’t always match the actual measurements, location and placements and pipe supports can arrive incorrectly sized.

Traditional fabrication methods, due to their welded nature, lack the flexibility for on-site modifications. Any alterations or adjustments often require supports to be sent back for off-site modifications, contributing to project delays and increased costs.

QMEXX shines in terms of modification flexibility. The QMEXX system is completely versatile. Should you encounter any site variations from drawings, supports can be instantly adjusted and adapted on-site to suit your exact site requirements. The clever multi-holed box section offers unlimited connection points enabling you to make attachments that can be instantly adjusted and adapted to suit your exact site requirements. Whether responding to unforeseen changes in site conditions or modifying supports to align with updated drawings, QMEXX provides a level of flexibility that traditional fabrication struggles to match.

Safety Considerations

Safety is paramount in any construction project, and the choice of a pipe support system can significantly influence on-site safety.

Traditional fabrication, especially when modifications are required off-site, introduces safety concerns. The reliance on temporary solutions, such as timber supports, during the modification process may pose risks to on-site contractors. The delay in implementing a fully customized support system can contribute to prolonged exposure to safety hazards.

And while there is no evidence to prove that traditional welded steelwork pipe supports are not as durable as QMEXX, there's also a lack of proof confirming that they are suitable for their intended purpose. This is because most traditional fabrications lack reliable load data, which could risk safety and compliance on-site.

QMEXX's availability of comprehensive loading reports is a standout feature in the realm of safety. These reports offer detailed insights into the structural integrity and load-bearing capacity of QMEXX components, with each part undergoing rigorous testing and analysis. This data-backed approach instils confidence in the system's ability to exceed industry safety standards. Furthermore, QMEXX's extensive usage in over 500 projects serves as a powerful testament to its reliability and adaptability across a diverse spectrum of applications. This real-world validation not only showcases the system's theoretical safety but also demonstrates its proven performance in practical, on-site conditions.

QMEXX also prioritizes on-site safety by eliminating of the need for temporary timber supports reduces safety risks associated with interim solutions. Contractors can promptly install QMEXX components when needed, minimizing potential hazards on-site.

Environmental Impact

As the construction industry increasingly emphasizes sustainability, considering the environmental impact of different pipe support systems becomes imperative.

Traditional fabrication methods may involve more on-site deliveries due to the inflexibility of modifying supports on-site. This can contribute to increased carbon emissions from transportation. Additionally, the potential need for frequent replacements and modifications may lead to a higher environmental impact over the long term.

QMEXX stands as an environmentally conscious solution with reduced carbon emissions. The off-the-shelf availability and instant adjustments contribute to fewer on-site deliveries, minimizing the carbon footprint associated with transportation. Additionally, the hot-dip galvanized finish enhances the longevity of components, reducing the need for frequent replacements and further supporting sustainability.

Long-Term Cost Savings

While upfront costs are a significant consideration, the long-term financial implications of the chosen pipe support system are equally vital. Assessing maintenance costs, modifications, and potential project delays paints a comprehensive picture of the long-term value.

Traditional fabrication methods may incur higher long-term costs due to the need for frequent maintenance, potential modifications, and the associated project delays. The inflexibility in adapting to on-site changes may lead to additional expenses, and the lack of verifiable load data also might lead to excessive wear and tear, and even failure.

QMEXX sets the stage for long-term cost savings. With reduced maintenance requirements and the ability to make on-site modifications without significant delays, the overall project costs are likely to remain lower over time. The lightweight design also contributes to potential savings in transportation costs and handling. Additionally, the inclusion of reliable load data to back your installations also ensure that your pipe supports are built to last longer.

Conclusion

In your pursuit of optimal above-ground pipe supports, it is essential to consider not only the immediate financial investment but also the long-term implications for your project. While upfront costs are a crucial factor, the profound impact of QMEXX on long-term savings cannot be overstated. QMEXX's durability reduces maintenance expenses, swift on-site modifications minimize project delays, and the lightweight design offers logistical efficiencies. In fact, the advantages of QMEXX extend beyond cost savings to encompass efficiency gains, safety enhancements, and a reduced environmental impact. It is for this reason that QMEXX stands as a frontrunner in the realm of pipe support systems. Empower your projects with a support system that not only aligns with your budget but propels your endeavours towards a future of enhanced efficiency, safety, and environmental responsibility.