As someone in the M&E industry, you are probably aware that misconceptions, mistakes, and outdated practices are ever-present.

You’ve likely even fallen guilty to some. Or maybe you aren’t even aware of the mistakes you’re making! After all, if something is working, why change it? But don’t worry, it’s not your fault, and it’s never too late to fix them. Besides, there’s a reason why this article exists, and that’s because these errors are just that common and many could benefit from reading it – so don’t feel bad!

We will break down some common misconceptions, explain what makes them wrong, and what you can do instead. These include:

- #1 Mixing & matching components

- #2 Using manufacturer's data as evidence

- #3 Overengineering = fit-for-purpose

- #4 “I’ve had no issues installing support bracketry this way, so it must be correct”

- Conclusion: confusing failure with evidence

#1 Mixing and matching components

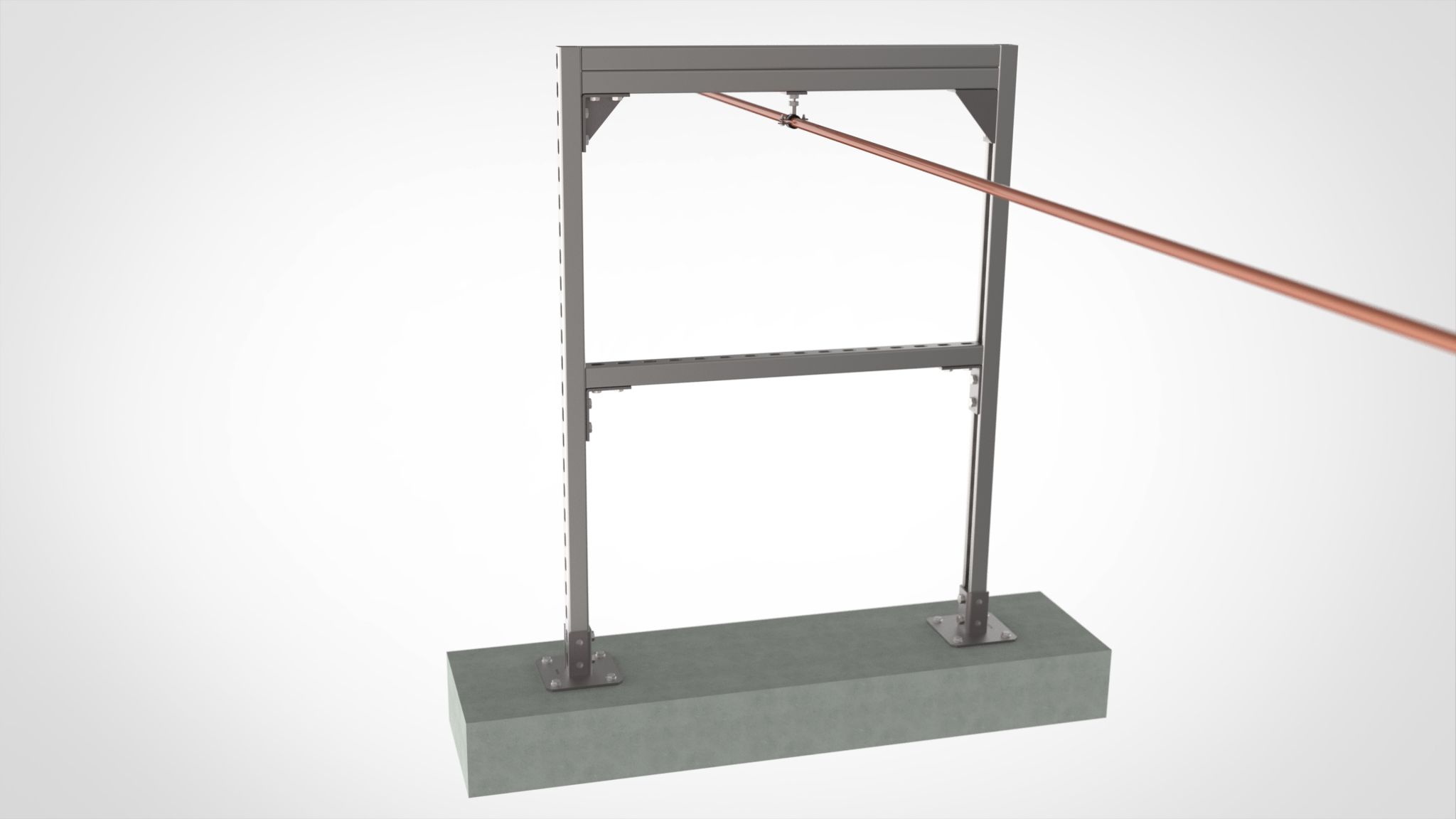

In M&E, it’s quite common for building services supports to be made by combining products of unproven joint performance, from various sources, into the installation. This obviously means that there is no data or information that indicates said combination would result in a safe and fully-functioning system, which can properly handle the applied loads. If you only have the data for one component, for example, the point load or UDL of a length of channel, once you bring in a separate component, all the data you have is now null and void because they haven’t been tested together. The Building Engineering Services Association (BESA) – Guide to Good Practice for ‘Supports and Fixings’ TR50 emphasises this as a fundamental flaw in the industry. It stresses that you should be able to demonstrate that the structure you’ve installed can take the load applied to it and that the supports and fixings are fit for purpose. In cases where components are mixed and matched, that isn’t possible, which is precisely why it shouldn’t be done. With that being said, the components that you use should be part of a system which has been tested together to prove their performance. This could be made of channel, Sikla Framo, or other; as long as it has data to back it up.

#2 Using manufacturer’s data as evidence

Please do NOT rely on individual manufacturers’ performance data as evidence. Most of the time, this load data doesn’t reflect the final installation and it is not comprehensive enough. Similar to the above point, you might be able to prove one aspect of a design with the load tables, however, you can’t prove the entire bracket structure. This is dangerous as it doesn’t take into consideration all of the potential loads and how the connections perform.

Something else to keep in mind is that other manufacturers’ channel products almost always use calculated data based on material performance, so it’s a desktop calculation rather than a physical application-based laboratory test.

At the end of the day, there’s nothing stopping you from doing what you want! But if your goal is to evidence your installs, the manufacturer’s data would not be sufficient. It hasn’t been proven through a test facility that these products work together, nor is there test data to define the upper limits of it. Ideally, you’d have application test data instead.

#3 Overengineering = fit-for-purpose

Often in M&E, people will ‘over-engineer’ a solution to ‘make sure’ it doesn’t fail – meaning they will deliberately use oversized and over-speced materials and/or components in the bracket assembly. But this doesn’t really prove anything. Whether something is over-engineered is usually determined by visual judgement rather than science or evidence. And it should be known that for a solution to be fit-for-purpose, it needs evidence to prove so. Taking a fleeting glance and saying “yep, that looks sturdy enough to me” is not evidence, believe it or not!

The issue at hand is not the risk of failure - although that is always important, it is unlikely to happen and most of the time, the installers ensure it won’t. However, what we do need is the evidence to prove that it won’t – the up-and-coming M&E contractor should understand this. For all we know, your engineered bracket could be volcano eruption-proof. But what good is it if there’s no evidence to prove that? It’s not fit for purpose unless you’ve got it.

To add to that, there’s always an optimum point where you can achieve the desired result with the least money. Spending any more money on materials past that point is redundant and wouldn’t make a real difference in the end result.

#4 “I’ve had no issues installing support bracketry this way, so it must be correct”

As mentioned, there are plenty of old-fashioned practices that the construction/M&E sector has been too stubborn to let go of. In particular, those who are experienced and have been in it for decades enjoy doing things the way they have ‘always done it’ as they believe it’s still the correct way. I don’t blame them; many of them haven’t actually experienced issues with their methods, so why would they change them? But while errors are rare, they still happen, and as an industry, we should put more effort into mitigating them by correcting our mistakes and perfecting our techniques - as much as possible at least. The first step of doing that is by reviewing your current methods – after all, isn’t the fact that you’ve done it this way for years and years a tell-tale sign that it may be outdated? That’s not an excuse; in fact, it should be the motive to change.

When so much effort, time, and trouble has gone into the design and specification of the complete bracket, there’s really no logic in squandering that by installing it incorrectly. Despite how much your data can prove, the biggest variable is the installer because there are a number of things that can be done wrong simply out of human error. Examples of commonly neglected issues are making sure the fixings and connections are torqued up to the correct torque values, being aware of when to use anti-corrosion spray coating (e.g. when channel ends are cut and raw material exposed), using and knowing why end-caps are important, knowing what to do when hitting rebar, and many, many more.

These are all cases that represent why bracketry installation is not something that can be done in a flash and off you go! But they can be ceased with a simple solution: training! By training, you’ll naturally have to step away from past methods and open your mind to more modern ones. Because of the volatility of the installer, they need to be able to demonstrate that they’re competent enough to carry out the install. To do that, they can be put through training programs and receive certification which can then be used as part of the evidence/’Golden Thread’ of information, along with the product data and evidence of the compliant installation.

Conclusion

You may have noticed that almost all of the aforementioned subheadings lead back to one common overarching misconception and that is: that it’s all about evidence and not necessarily failure. You may well be doing everything perfectly, and that’s fantastic, but there’s almost no point if you can’t prove that you’ve done so. By joining the growing movement towards compliance and evidence, you would only be benefiting and helping yourself, your reputation, as well as your projects.

In any case, whether or not you fell victim to any of the common misconceptions mentioned, I hope this article has helped you better understand why evidence and general compliance are important when it comes to bracketry in M&E.