The M&E sector is evolving, and if you feel like it’s hard to stay ahead of the constant changes and revised best practice, that’s understandable.

As an M&E contractor, you might be aiming to discover something ‘different’ to set you apart and not be dragged into the race to the bottom of a dog-eat-dog price war. You may genuinely want to be better to make a difference and care about the bigger picture. But, you also may not know where to start, and that’s why we’re here.

Whilst we know change is daunting and can seem burdensome, it can bring tremendous opportunities to stand out. Here are some things you can do to get started:

- Provable building services supports

- Continually upskill your workforce in line with the most recent best practice

- Use tested and identifiable systems

- Optimised support solutions

- Embrace an early engagement mindset

- Adopt a ‘right-first-time’ approach

- Keep abreast of everything that is changing

Provable building services supports

If you’ve read some of our previous articles, you probably will have noticed our emphasis on provability and evidence-based systems and why that’s important. If not, let’s get you up to speed!

When discussing evidence with contractors, more often than not they admit that they don’t have evidence to back up their M&Es support bracketry installations, simply because they think or ‘know’ that “the install won’t fail”.

By that logic, installations are mostly based on judgement rather than science and therefore are not provable. If challenged, you’d have no way to prove that the bracket you’ve just installed can safely carry the load.

9 out of 10 times, the support will not fail, however, you need to be able to show why it won’t and how you made sure of that. Otherwise, pure belief and word of mouth are not proof.

An example of how evidence can be integrated into your installations is by making sure the brackets at least enter the Design stage. This way, the necessary calculations can be made, giving you proof that it is fit-for-purpose by default. Oftentimes, brackets are not even designed but just assembled on site, making them completely unprovable.

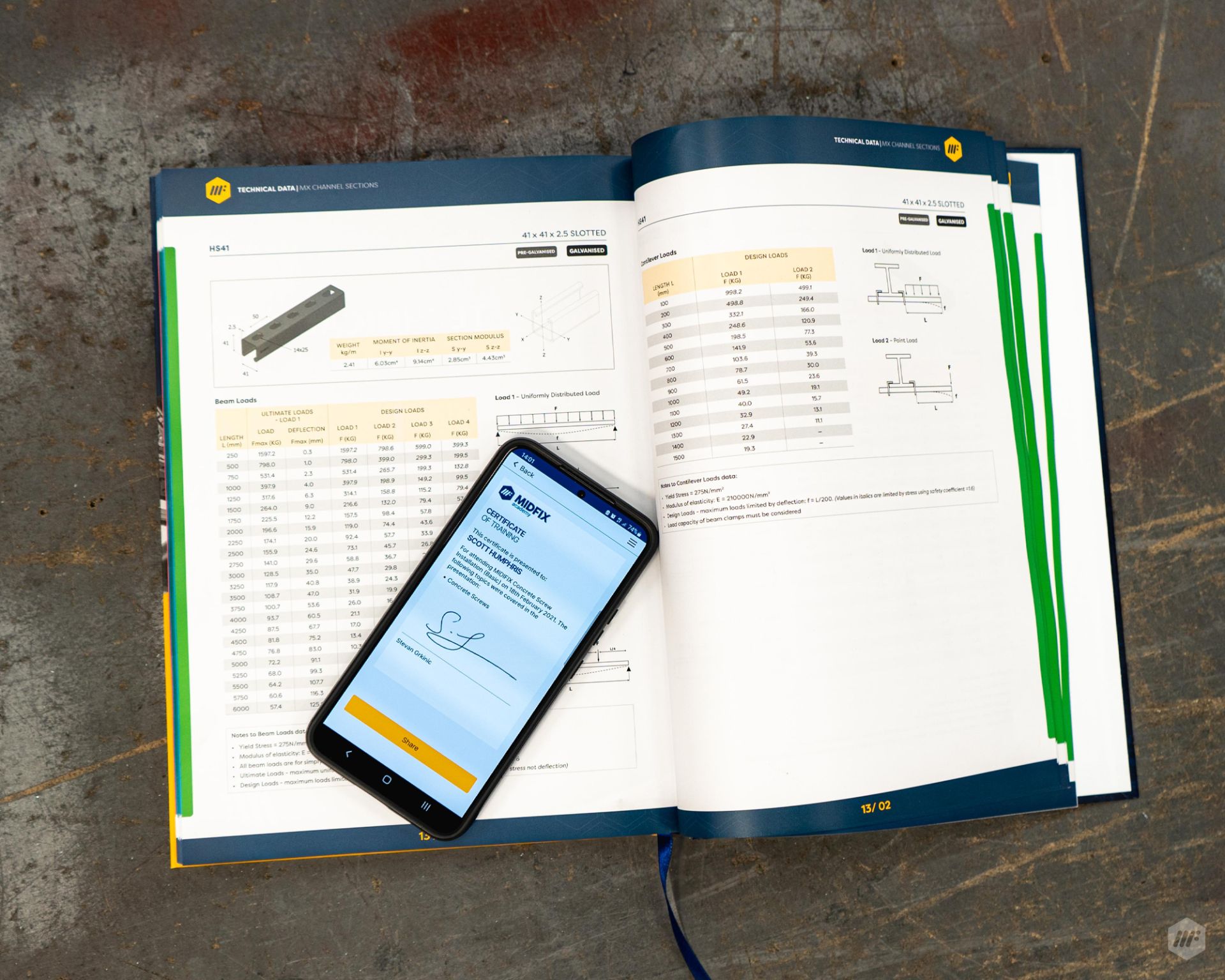

Using an evidence-based system such as a tested channel system (like the MIDFIX MX Channel System) would also solidify that the complete bracket will perform safely. This depends on the type and complexity of the bracket; for simpler, common and repetitive designs like trapeze brackets, it would be sufficient. However, for others, you may need to engage with a support bracket design specialist that can design and calculate based on your requirements.

Regardless, what you ultimately are looking for is sufficient evidence that demonstrates it can perform. The same applies to using the recommended ETA anchor which has already been through the necessary testing to assure it’s fit-for-purpose. Don’t stray from the specification because that anchor is chosen for a reason and the evidence behind it already exists.

But why is this so important?

Well, if nothing else, there is the logical reasoning which is to be sure of your supports’ performance and have peace of mind. Besides that, more Tier 1 contractors are increasingly beginning to ask for proof behind installations, and it’s even going to become a legal requirement soon.

The evidence forms part of the ‘golden thread of information’ which was mentioned in the 2018 Hackitt report. It is a key element of the Building Safety Bill that was granted Royal Assent and became an Act on the 28th of April 2022. It will be required of duty-holders to maintain comprehensive records of information for higher-risk buildings, including how they’re constructed, how safety is designed into them, how they’re going to be maintained, etc.

While this is quite specific to high-rise buildings, this is only the beginning and legislation like this will spread across all areas of construction, and M&E installations will also need to be backed up. According to the government’s timelines for the Building Safety Act, this, including the golden thread, could come into effect as early as April 2023.

.png?width=6000&name=MicrosoftTeams-image%20(480).png)

Using tested and identifiable systems

Following on from the last point, if you’re using evidence-based components or systems you will need something to prove that you are i.e. to be able to identify that such and such components are backed up by evidence.

It’s not always the case that products that have been through testing and are compliant are also marked, although theoretically, it should be.

A simple marking on each of the components is what allows you to trace them back and identify them to be evidence-based. If not, then how would you tell that these products being installed are the same ones that were specified?

This applies to both systems like the MX Channel Systems to prove that the components are part of a cohesive system, as well as individual components. For example, ETA anchors are typically marked in order to be easily identifiable that they are in fact compliant.

Essentially, you’re looking for products that are marked with a logo or name of some sort to say, ‘this is what was supposed to be used and here’s the proof.’ Simple as!

Continually upskill your workforce

In line with the most recent best practice, installers must be trained and competent to install any M&E support bracket according to the manufacturer’s installation guidelines.

Look at it this way: logically thinking, would you take on a challenging task that may result in injury, or even death, if done incorrectly, without training for it? I would hope the answer is no!

Unfortunately, though, this is the case with many M&E installations, as installers carry out installations with little to no training. This is understandable; after all, most fixings and bracketry are simple to install and you may well have been doing it a certain way for many years.

However, recent best practice guidance has deemed long-standing working practices non-compliant. In fact, installers will frequently reach an epiphany during training that they’ve actually been doing things wrong and end up changing their working practices, thanks to what training helped them understand! You’ll be surprised by how much you can learn.

So, who in their right mind would willingly choose not to be doing the job correctly? That’s why installer training is so important – it’s one thing to design the bracket based on evidence, but it’s another thing to show that it’s been installed competently, too.

Training isn’t as expensive as you may think and the value in encouraging training for all installers & supervisors for both bracketry and anchors and fixings could save the potential cost of a suspension failure, let alone reputational loss.

When you finish your training, the certificate that you’ll receive is what will count as evidence of your competence as part of the golden thread.

“Investing in improved competence levels could ensure that more skilled workers are able to correct errors and improve efficiency alongside ensuring compliance with the regulations."

- Dame Judith Hackitt, 2018

"Building a Safer Future: Independent Review of Building Regulations and Fire Safety"

Optimised support solutions

We’ve mentioned in other articles that a frequent occurrence in M&E is deliberately selecting oversized and ‘over-specced’ material and/or components for the bracket assembly, in an attempt to ‘ensure’ it doesn’t fail. The thing is, we’re not necessarily worried about the support physically failing, but rather having the proof that it won’t.

While your heart may be in the right place, this doesn’t actually prove anything because, once again, it’s based on judgement rather than real proof or science. To prove that a bracket is fit-for-purpose and can safely perform, you need tangible evidence, and not just visual assessment – you can’t just say ‘looks good to me!’ and call it a day.

On top of this, the goal is to reach the optimum point which is where you can achieve your desired result with the least cost. Spending any more money past this peak is redundant and wouldn’t make a real difference in the result, and over-engineering is an example of crossing this peak unnecessarily.

In reality, over-engineering is likely to be costing you more than it is benefitting you.

As if that’s not enough reason, it’s also highly unsustainable because the more material you use, the more carbon you will be emitting. And with the Net Zero 2050 goal of decarbonising all sectors of the UK economy, we should be aiming to reduce embedded carbon as much as possible.

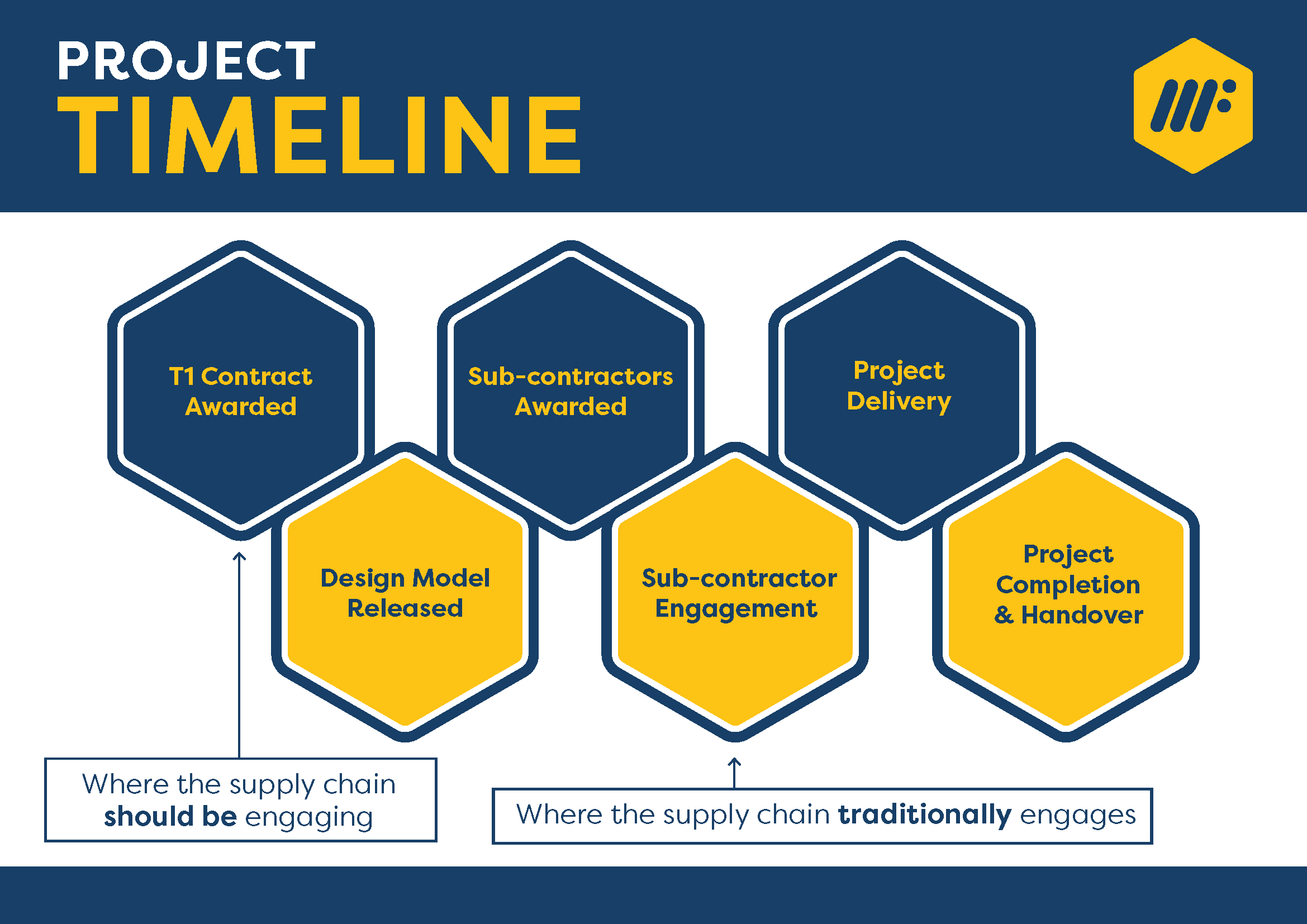

Embrace an early engagement mindset

This point would almost automatically be a precursor to all of the above points, as well as additional ones. If you aim to implement some (or all!) of the points made in this article, you’d have to already be thinking ahead and engaging early in order to successfully do so.

Another example is dealing with anchor testing and policy at the design stage, with a specification approach in mind. This same approach that is being applied to supports and fixings can trickle down throughout the project, improving your chances of achieving the above goals.

If the mentality of early engagement as a principle and handling supports at the design stage can become embedded into the organisation’s culture, then it’s only for the better. Here’s to constant improvement!

Adopt a ‘Right First Time’ approach

If you set your mind to it and introduce all the above functions to your work, you’re greatly increasing your chances of getting your M&E installation right, the first time (see what we did there?).

In doing so, you’ll be able to build a reputation of having a RFT approach. You’re on the ball with compliance, competence, tested systems, optimised supports, and have embraced early engagement. What more could you (or the Tier 1 contractor) want?!

You’d only be helping yourself by gaining a competitive advantage and reducing the risk of costly rework in the future should something fail.

Keep abreast of everything that is/may be changing

Considering how much has already changed in our industry over the last 5 or so years, it shouldn’t come as a surprise if and when more changes occur. In fact, we should be prepared for that.

There are many standards and regulations that have come into play with regards to not only supporting services but the services themselves, too e.g., installing pipework, cable, etc.

We’ve seen so much happen, from the 2017 Grenfell tower fire, to the 2018 Hackitt report, to the BESA TR50 supports & fixings guidance document, to the Building Safety Bill, being turned into an Act, the 18th edition wiring regulations for fixing cables, etc. etc. and that’s only scratching the surface.

There’s more that’s waiting to happen in the future that we probably aren’t aware of. So, keeping up to date and abreast will mean you won’t be shocked or caught off guard if you have to alter some of your practices; once again giving you a competitive advantage.

The point is, as a principle, you should be open to change, adaptable, and be learning and looking out for it ahead of time, even before legislation. You can never be too prepared!

Conclusion

Not only will the aforementioned processes help you win more projects, but they will also generate a more meaningful and fulfilling sense of purpose within the culture of the organisation.

It will inspire your workforce to be the best and a part of something that is much bigger than the usual rat race. Furthermore, you’ll become much more attractive to principal and Tier 1 contractors, simply because they cannot do without you!

You’ll become an active part of moving the sector forward and adding value to the industry for future generations. That’s something that money can’t buy!

.png?width=451&height=381&name=MicrosoftTeams-image%20(480).png)