In M&E, some organisations in the supply chain offer a CAD Design service, and they make it easy to assume that they are the answer to all of your needs when it comes to bracketry design.

In some cases, they may be, but in other cases, they likely aren't. However, we understand that a lot of it comes down to terminology and qualifications, making it quite confusing.

Our goal is always to make it as easy as possible for you to understand so that you can make the right choice. That’s what this blog is for! Keep reading or navigate this article by clicking on the subheadings below.

- What is a ‘CAD Technician’?

- What is a ‘Design Engineer’?

- How do the roles differ?

- How do I know which one I need?

- When would a CAD Technician provide sufficient evidence?

- Conclusion

What is a CAD Technician?

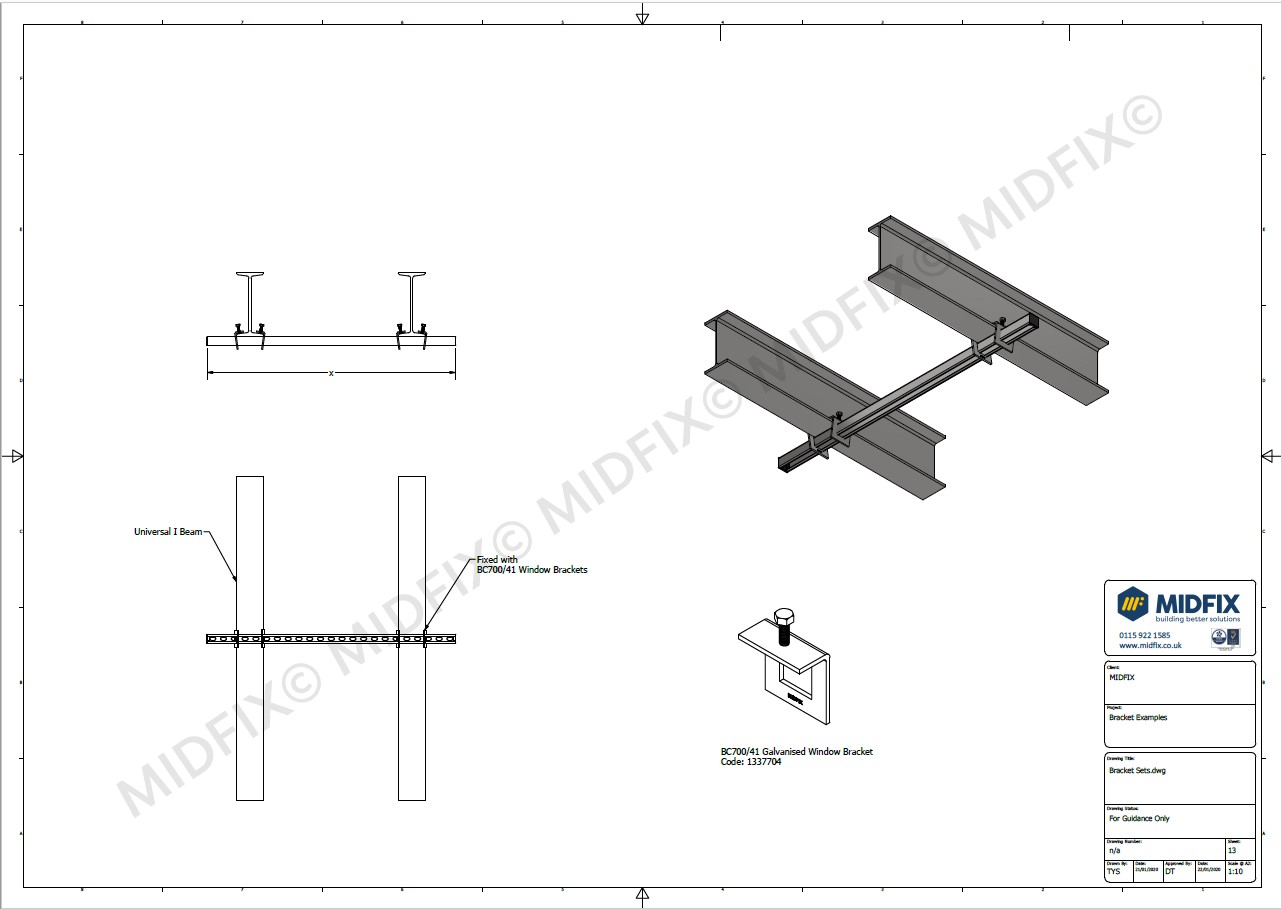

CAD Technicians use software to create technical drawings and/or models for both simple and complex projects. These may be simple 2D drawings or 3D parts and assemblies, and are for products used in M&E, construction and manufacturing. CAD Technicians are often given a sketch and any relevant information, and then produce a model and drawing off that.

An illustration of basic CAD drawing.

An illustration of basic CAD drawing.

What is a Design Engineer?

Design Engineers take a model or sketch from the customer and look at how best to design something using engineering principles i.e. they have a deeper understanding of what components can be used for a design and what the benefits and drawbacks of placing those components together are. They typically have a degree and are experienced at running checks and calculations to prove their designs.

How do the roles differ?

For starters, from a qualifications standpoint, as mentioned they usually don’t both require a degree, although for Design Engineer roles this is a large advantage. But from the point of view of the M&E market, the biggest difference is the outcome i.e. what do you want from the design? Many will assume that CAD Technician is sufficient to engineer designs, which is far from the truth. They might have the qualifications and skills to use the design programs/software, but not the mechanical engineering skills to be able to engineer, nor to provide evidence that an M&E support design is fit-for-purpose. On the other hand, a Design Engineer does.

How do I know which one I need?

The desired outcome is what determines which one you should pick. Unfortunately, oftentimes it’s just another box to tick. A key deciding factor is having a piece of paper to show that the bracket has been (or appears to be!) designed, so the model, though not engineered, is sufficient. But this is a flawed outlook because it’s not real evidence. Plus, if you’re going out of your way to do that, why not commit to it properly and ensure that it’s engineered so they’ve got the most optimum solution? You might as well; that way you not only have proof but you’re sure that it is fit-for-purpose.

Price and time are also influencing factors although they shouldn’t really be. Believe it or not, CAD designs can actually be done retrospectively, but as if they were done prior. This isn’t uncommon in our sector when Tier 1 contractors ask for design papers after the fact, as a last-minute solution.

In contrast, to design and engineer something properly, it’s best to engage as early as possible, so this sadly but understandably is off-putting to some. Nevertheless, you shouldn’t rely on a CAD Technician to provide you with substantial evidence showing that an M&E support design is fit-for-purpose. With a standard CAD design service, there’s no assurance that it’s been engineered and calculated. That means nothing indicates that it’s an optimal solution.

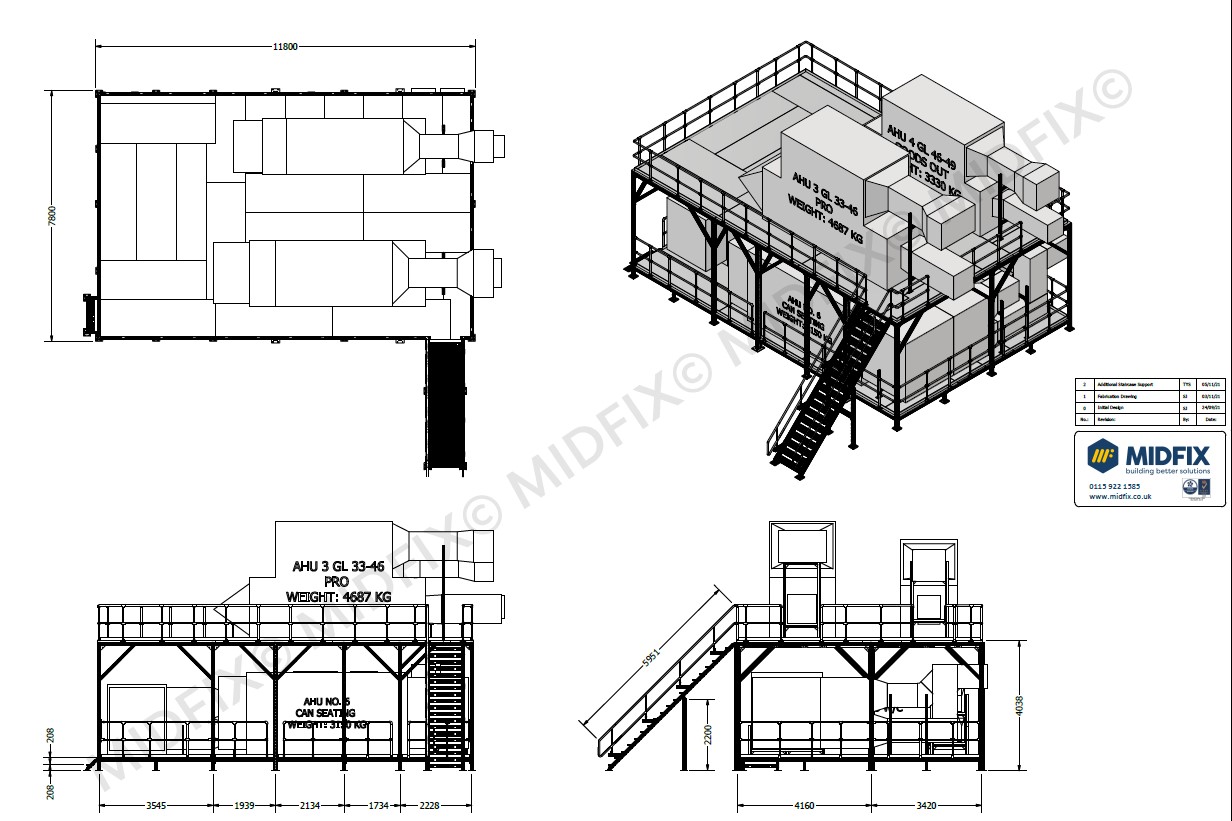

A Design Engineer would be best suited for these projects..

The alternative and usually the best option that some organisations offer is services from a Design Engineer. Them having both the skillset related to mechanical engineering rather than just knowing how to use CAD programs means they have the understanding of the principles that will affect the design, and as mentioned, demonstrate that it’s the best and most suitable solution.

However, it’s easy to get them mixed up, both because of the universal lack of understanding of the differences between the two rules, as well as companies often being misleading about their services. Some contractors will go to an organisation that is mis-selling their function, thinking they’re getting an engineered solution when in reality it’s just something being modelled. Also, not all suppliers in the marketplace offer Design Engineers for supports, so they may not be as easy to find.

-1.png?width=944&name=MicrosoftTeams-image%20(452)-1.png)

A snapshot of the calculations provided for an M&E support by a Design Engineer.

When would a CAD Technician provide sufficient evidence?

The only time using just a standard CAD drawing is adequate is when you’ve got the assurance that the engineering/calculations had been done prior. This way, the CAD Technician can be given the correct instructions to model it into a model/drawing and still arrive at the best solution. Some M&E organisations have their own design department where they will design certain aspects of it. In those cases, they might’ve done the calculations, and sent the details of it to a CAD Technician to document it, making it fit-for-purpose. Otherwise, you’ll need a qualified engineer.

Conclusion

In summary, the Design Engineers are more involved in the actual design and engineering of the bracket (including calculations etc.), while the CAD Technician is often simply transferring sketches and drawings from the engineers’ initial designs to a more formal and consistent format. In a firm with both roles, the Design Engineer does the design and calculations, while the CAD Technician is responsible for the drawings/models. A CAD Technician doesn’t have the qualifications or experience to arrive at the most optimum engineered solution - if that part has already been done, then that’s when they can become involved in the model.

References:

- Noble Desktop. 2022. What is a CAD Designer? Explore the CAD Designer Career Path. [online] Available at: https://www.nobledesktop.com/careers/cad-designer

- Prospects, 2020. CAD technician job profile | Prospects.ac.uk. [online] Available at: https://www.prospects.ac.uk/job-profiles/cad-technician#:~:text=A%20CAD%20technician%2C%20also%20known,engineering%2C%20c+onstruction%20and%20manufacturing%20industries