For decades in the construction sector, dust has been swept under the rug (no pun intended!) time and time again.

But this is no longer an option if we want to work towards reducing health risks and deaths in the industry – as dust is much more of a detriment than you might think. If you haven’t taken the necessary precautionary measures to prevent dust in your M&E projects, don’t worry, you’re not alone. But, something needs to be done about this. That’s why we’ve written this article which will discuss the following:

- What is dust-less drilling?

- Why is dust-less drilling so important?

- What steps are you responsible for taking to reduce dust on site?

- What does this mean for M&E Contractors?

- Conclusion

What is dust-less drilling?

When drilling into a substrate such as concrete, the method of extracting dust particles out of the drilled hole before it reaches the environment overcomes the problem of dust; leading to what we call “dust-less drilling”.

Why is dust-less drilling so important?

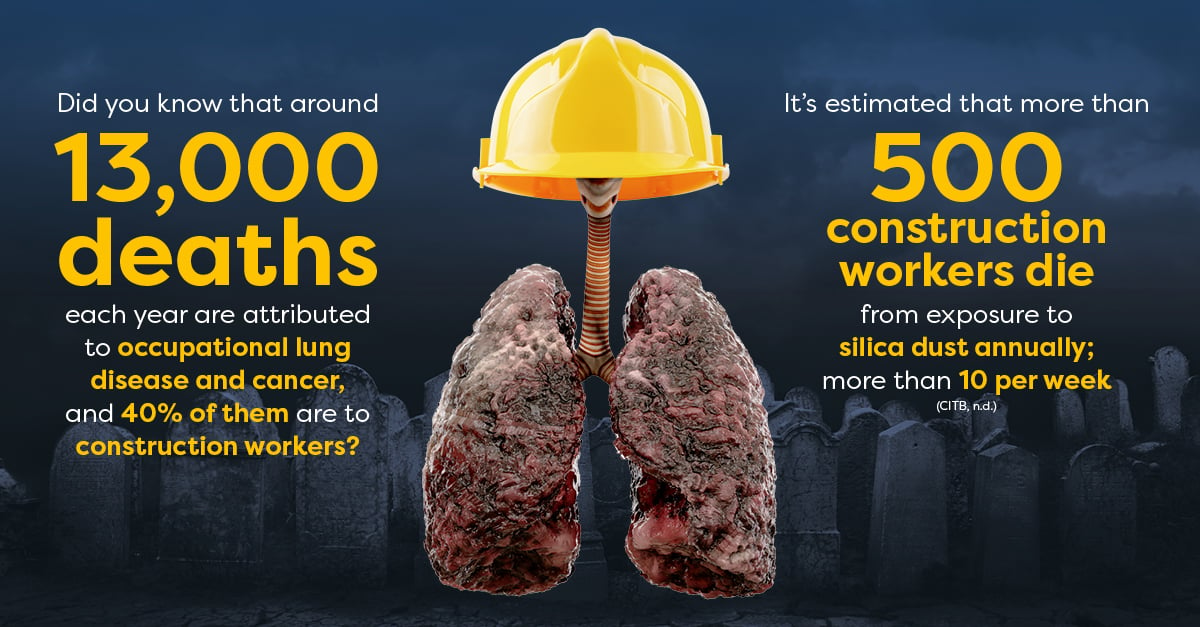

It may be something that hasn’t even crossed your mind before as it’s not talked about enough – but it’s truly underestimated and misconstrued just how harmful dust actually is to your health. Here are some surprising statistics: did you know that around 13,000 deaths each year are attributed to occupational lung disease and cancer, and 40% of them are to construction workers? It’s estimated that more than 500 construction workers die from exposure to silica dust annually; more than 10 per week (CITB, n.d.) Convinced yet?

Silica is a substance naturally found in certain types of stone, rock, sand, and clay, and it can easily be inhaled when made into very fine dust, causing inflammation and scarred lung tissue (fibrosis) i.e. silicosis (NHS, 2021). It’s the second biggest killer of construction workers, after asbestos. There’s also wood dust, found in softwood and hardwood, and mixed dust which is produced from cement, limestone, marble, and more. Other dust-related diseases that are sure to affect construction workers include lung cancer, asthma, and chronic obstructive pulmonary disease (COPD). The reason is that common tasks assigned to them, even things as simple as cutting, earthworks, stockpiling, and more can create very high dust levels. The longer the exposure, the greater the risk of getting any of these diseases – although some can appear quite quickly, such as asthma or advanced silicosis (HSE, 2020).

On top of all of these health risks, dust is also just a nuisance. Neighbours will often complain about dust coming from a demolition site into a public area, or from loading and unloading, transport and storage, etc.

Moreover, the BS:8539 Code of Practice for installing anchors into concrete says dust and debris need to be removed from drilled holes. This is not only because they won’t impact the anchor’s working principle, but also because it ensures the anchor will have the correct space within the hole to reach its intended embedment depth.

Taking all of this into consideration, hopefully, you now understand its gravity and why it’s imperative to prevent dust when drilling. But, how can you do so?

What steps are you responsible for taking to reduce dust on site?

According to The Control of Substances Hazardous to Health Regulations 2002 (COSHH), there are three key things you should do when dealing with dust:

- Assess the risks

Think about the task itself: does it require much energy? High-energy tools such as cut-off saws, grinders, and grit blasters produce copious amounts of dust in a very short time, accelerating the risk. Moreover, while tightly enclosed spaces will likely result in more dust build-up, dust levels can still be high when working outside with such tools. Lastly, I’d say it’s self-explanatory that the more work there is and how frequently it’s being done also greatly increases the risk.

- Control

This is the most important step. There are a few different ways you can control the risks depending on the task you are executing. The first of which is to stop or reduce the dust prior to starting work. This can be done by using different materials and/or tools. We’ve established that high-energy tools tend to produce much more dust- so switching to something less powerful such as a block splitter may help significantly. Also, you should try to measure out exactly the right amount of material you will need so that less cutting and preparation is required, avoiding unnecessary dust production. In most countries, it’s now forbidden to use abrasives containing more than 1% free silica for blasting due to the risk of Silicosis (Gritco, n.d.). Switching to silica-free alternatives overrules this.

However, no matter how much you try to reduce the amount of dust produced, it’s unfortunately bound to happen with this kind of work. What you can do, however, is to most importantly stop the dust from reaching the air – because, once it is airborne, it’s much more difficult to control. To do this, you can either: 1. Use water to dampen down the dust cloud. A common mistake, though, is only wetting the material beforehand. Instead, enough water should be supplied throughout the entire time the labour is taking place. Or, 2. On-tool extraction: remove dust as it’s being produced. Local exhaust ventilation (LEV) systems can be fitted directly onto tools and used to do this – don’t just use a generic vacuum!

Vacuums for general site use should always have a high-efficiency particulate arrestance (HEPA) air filter, which is designed to capture very small pollutants and particles. General mechanical ventilation also doesn’t hurt to use.

Regardless of whether you take these precautions, however, you should always use respiratory protective equipment (RPE). This typically has an assigned protective factor (APF) that determines its adequacy for the application and amount of dust. It should also be comfortable enough to be worn for many hours, compatible with other equipment, and worn and fitted correctly.

Finally, some other ways to control the impact of dust (in combination with the aforementioned) are to limit the number of people near the work and working in rotation (reducing each person’s exposure). Using sheeting or screens to enclose the work will also help to stop the dust from escaping. Remember, though – these are not enough on their own and neither is just using RPE. Take all the measures necessary and possible to ensure safety.

- Review

After you’ve done everything you can to control the dust, you need to make sure they’re working correctly. Fair enough, right? Obviously, you should have procedures in place to double-check that the work is being done right. Other than that, you should keep an eye out for dust – does it seem like the controls aren’t effective in reducing dust levels? If so, something needs to be amended. Workers can help identify problems as well, so keep them involved, while also supervising them to verify their methods. You should also undergo maintenance for the equipment used by following maintenance instructions, looking for signs of damaging and repairing when necessary, properly cleaning and storing RPE, and carrying out tests annually.

Much of this information was taken from the HSE ‘Construction dust’ Information sheet.

What does this mean for M&E contractors?

As mentioned, removing dust is essential for high-quality anchor installations. When it comes to M&E contractors, dust is an issue most commonly faced during this stage. To overcome this, there’s a product called a dust-extraction drill bit that allows you to drill and extract dust at the same time. In order to use this compliantly, you need to use an M (Medium) class vacuum with it which is used for higher hazard substances. This would then tackle the problems that dust will pose when drilling into a substrate such as concrete i.e. dust-less drilling.

Conclusion

Dust is an ever-present danger in the construction industry that at first glance might seem somewhat harmless. But with the many risks that lead to sickness and even death, it should be standard procedure to try to prevent dust and reduce its impact while on site. I hope this article has inspired you to take better care of yourself and others and be wearier of dust at work. Not only is that imperative from a health and safety perspective, but it also would improve the standard and quality of anchor/fixing installation, which is always welcome. Stay safe and good luck!

References

CITB. 2020. Construction Information Sheet No. 36 (Revision 3). [online] Available at: <https://www.hse.gov.uk/pubns/cis36.pdf/> [Accessed 19 April 2022].

NHS. 2021. Silicosis. [online] Available at: <https://www.nhs.uk/conditions/silicosis/> [Accessed 19 April 2022].

CITB, n.d. Why is dust a problem? - CITB. [online] Available at: <https://www.citb.co.uk/about-citb/partnerships-and-initiatives/construction-dust-partnership/why-is-dust-a-problem’ [Accessed 19 April 2022].

Gritco. n.d. Can I use just any sand for blasting?. [online] Available at: <https://www.gritco.com/can-i-use-just-any-sand-for-blasting> [Accessed 19 April 2022].