Following the Grenfell Tower Tragedy, the Building Safety Act of 2022 was enacted to establish stringent regulations to ensure safety and competence in the construction industry. It mandates that all installations, including those by the M&E sector, provide verifiable evidence of their capability to perform their designated tasks accurately, thus prioritizing consistency, traceability, and reliability.

But what does this mean for you, as an M&E contractor?

This means that Tier 1 contractors now have the added responsibility of proving that they are indeed competent. This eventually creates a ripple effect, as Tier 1 contractors now expect subcontractors to provide all the necessary information and documentation to back their projects. Much of this

Simply stated- just claiming to be competent is no longer enough. You need to be able to prove it.

Anchors and Fixings – why are they important?

Much of this governance has been channeled into improving the safety and compliance of anchors and fixings. Why, you ask? This is because most anchors and fixings are Safety Critical i.e., are located overhead and could therefore result in significant human and monetary loss upon failure. Therefore, Tier 1 contractors often place special emphasis on subcontractors to demonstrate that their anchors installations are selected and installed competently, usually in accordance with the BS 8539:2012 Code of Practice.

While the BS 8536:2012 is not a legislative act, it is a code of practice that guides all stakeholders involved in the supply chain of anchors – from designers and manufacturers – through the safe selection, supply, installation, and testing of anchors.

But remember – the focus is not just on being compliant but proving that you are!

So how can you prove that your business is following the BS 8539 Code of Practice?

This article delves into the intricacies of how you, as an M&E contractor, can demonstrate that your anchor installations meet the expectations of your Tier 1 contractors.

This is what you can do to show that your installations are up to standard:

- Have a Fixings & Anchors Policy

- Hire an Experienced Site Supervisor

- Pay Attention to Fixings Boards

- Ensure Correct Torque Settings

- Conduct Site Testing

1. Have a Fixings & Anchors Policy

In accordance with the Building Safety Act, many Tier 1 contractors have what is known as a Fixings & Anchors Policy.

.png?width=5292&height=3729&name=MicrosoftTeams-image%20(747).png)

A Fixings & Anchors Policy is a set of minimum expectation guidelines that M&E contractors must follow when it comes to anchor compliance. It may be handed to you at the start of any anchor installation project, and it is your responsibility to not just follow, but also procure the necessary documentation to prove that your installations are in line with the Tier 1 contractor’s Fixing Policy.

However, it doesn’t always end there. More and more Tier 1 contractors are expecting their subcontractors to take a step further and devise their own Fixings and Anchors Policy. What this means is that M&E contractors are now expected to devise detailed documentation to demonstrate how their company is following the best practices when it comes to anchor compliance.

A Fixings and Anchors Policy may include the following:

- An overview of anchor compliance in relation to the project, and how the company aims to fulfil the requirements of the BS 8539:2012 Code of Practice.

- Best practices being followed when it comes to anchor selection, supply, installation, and testing, including installer training.

- The roles and responsibilities of all stakeholders during the anchor installation project.

- Quality-control documentation enabling supervisors to record, log and sign off all anchor installations.

Having your own Fixings and Anchors Policy works in everyone’s favour. It reassures Tier 1 contractors that you, as a subcontractor, are doing your due diligence to ensure that your anchor installations are fit-for-purpose and can take the service load applied to them. It also protects you in case something does go wrong, by giving you the documentation to prove that your fixings and anchors have been installed correctly.

2. Hire an Experienced Site Supervisor

In most cases, M&E contractors are expected to have a Site Supervisor that is experienced and knowledgeable about anchors. This is because the site supervisor is the one responsible for signing off an anchor installation prior to the anchor being loaded, and for verifying that the entire project is in line with the Fixings and Anchors Policy (whether that be yours or your Tier 1 contractor’s).

According to the BS 8539, your Site Supervisor is responsible for the following:

- Making sure the correctly specified anchor has reached the site and installation teams.

- That the base material condition and hole dimensions are as specified.

- That the anchor position matches the design (embedment depth, anchor location etc.)

- That anchors have been installed correctly - in line with the manufacturer’s instructions, the design criteria, by trained & competent installers, and using the correct setting tools.

- Finally, once the installation is done, the supervisor signs it off and carries out the final checks.

For these reasons, many Tier 1 contractors want their subcontractors to invest in supervisors that are trained and experiences in all areas of anchor installation and anchor technology.

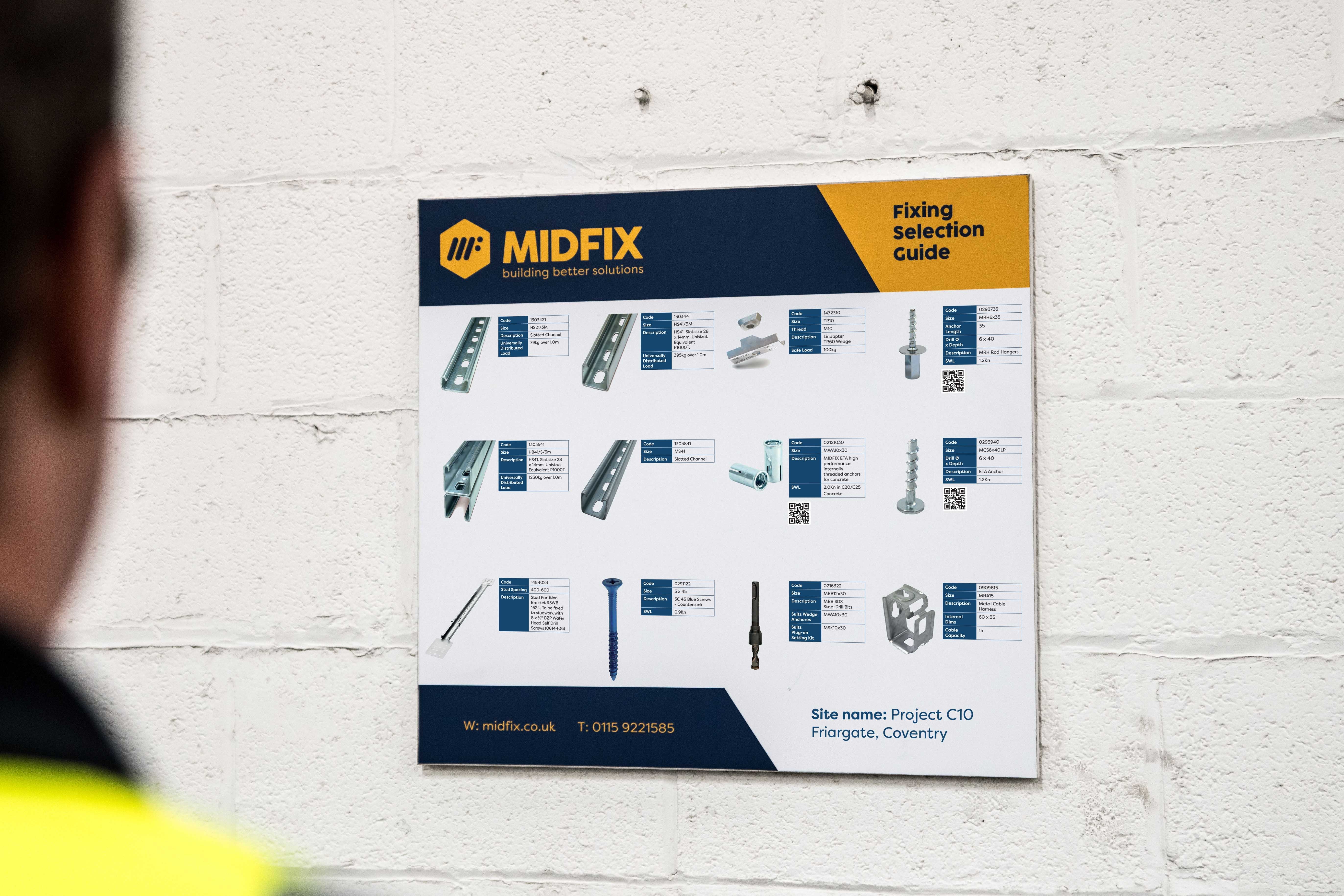

3. Pay Attention to Fixings Boards

As an M&E Contractor, how do you know that you have selected and installed the correct anchors and fixings in your project?

That is why we have fixings boards!

Many Tier 1 contractors either provide fixings boards or require the M&E contractor to create their own. Fixing boards include a list of all the specified fixings that are being used in a project, and the precise location in which they are being used.

It is the duty of the M&E contractor to use the correct fixings as specified on the fixing boards in their correct locations.

However, in case the specified fixing is not available or cannot be supplied onsite, the M&E contractor must adhere to the Change Management Procedure (as detailed in the BS 8539:2012 Code of Practice) if asked for alternatives.

Oftentimes, depending upon the Anchors and Fixings Policy of the Tier 1 contractor, this might require re-gaining the approval of the Tier 1 contractor prior to installation, so that the specified anchor matches their ‘tech-sub’.

4. Ensure Correct Torque Settings

Did you know that 80% of all anchor failures are because the anchor has been installed incorrectly?

The BS 8539:2012 has a simple solution to this: The anchor must be installed and supervised by trained and competent individuals, as per the manufacturer’s instructions.

While this sounds straightforward, historically speaking, the torque settings provided by the manufacturer is most often overlooked by M&E contractors.

.png?width=3840&height=2160&name=MicrosoftTeams-image%20(753).png)

For this reason, it is becoming increasingly common for Tier 1 Contractors to conduct quality inspections on the torque settings used during anchor installation, alongside requesting installers to produce photographic evidence of the torque values.

It is, therefore, important that the M&E contractor places special emphasis on using a torque wrench with a valid calibration certificate and ensure that all Fixings are torqued to the right value. Don’t forget to record this for evidence!

5. Conduct Site Testing

According to the BS 8539:2012, testing the strength of an anchor is not required if an ETA-approved anchor has been installed into a known substrate.

However, more and more Tier 1 contractors are demanding that regardless of whether or not the anchor is ETA approved, allowable load testing is mandatory. In this case, M&E contractors should be prepared to carry out testing by a CFA approved tester and provide detailed reports of the same.

Conclusion

While much of what we have discussed is just a repetition of what has already been stated in the BS 8538:2012, perhaps the largest takeaway of this article is – Show, don’t tell!

While following the BS 8359:2012 Code of Practice is becoming a standard expectation of most Tier 1 Contractors, there is now an added requirement of providing all the satisfactory evidence to confirm that this has been done competently, in accordance with the Building Safety Act.

While many times, this means having a knowledgeable site supervisor to record and sign off your anchor installation process, it may also mean going a step further to formulate a Fixings and Anchors Policy even prior to the bid phase, to demonstrate to Tier 1 contractors that you can be trusted to follow the best practices when it comes to anchor installation. Not only does this help your business win more projects with the higher-ups, but it also ensures that your company is already playing its part in building a safe and stable future.

.webp?width=1200&height=627&name=MicrosoftTeams-image%20(362).webp)