As the M&E and Construction industry continues to make changes in order to improve and develop, we as MIDFIX and M&E specialists, decided to think of innovative ways to optimise bracketry designs.

In turn, we produced MX – our version of a tested channel system for engineered supports. We also know that AHU/rooftop plant support frames are a very common design, and whilst they do vary to an extent in material and lengths, they are more or less repetitive designs.

Off the back of that, we concluded that plant support frames could be fine-tuned to be much more efficient, convenient, and effective. That’s when the MIDFIX MX-R Channel Frame Modular Roof Support System was born, and the rest is history!

Don’t worry, you can just call it MX-R. Now let’s get you acquainted.

- What is an MX-R Support Frame?

- How is an MX-R Support Frame different to other channel-based rooftop plant support systems?

- What makes MX-R ‘truly modular’?

- How do I configure an MX-R Support Frame?

- How easy is it to assemble an MX-R Support Frame?

- What are the limitations of an MX-R Support Frame?

What is an MX-R Channel Frame?

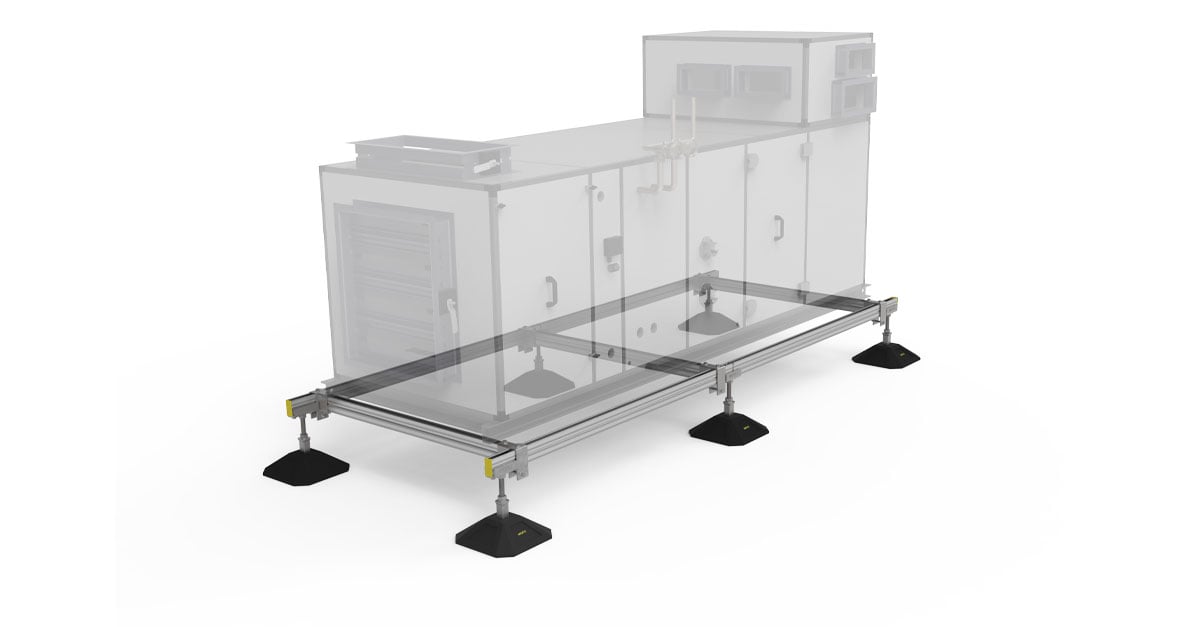

It is a truly modular frame system for supporting light to medium-duty roof-mounted HVAC equipment including AHUs, chillers, condensers, and others.

MX-R Support Frames can be based on either single or double-channel profile and a compact range of components, making it simple to configure almost any size of frame with unlimited adjustment.

How is an MX-R Support Frame different to other channel-based rooftop plant support systems?

Up until now, what you’ll find with traditional plant support frames is that they will be made partly of channel and partly of box-section, or they will have welded connections onto the channel.

What the MX-R Support Frame does is circumnavigate the entire concept of welding and adapting channel for a certain use; there’s no need to do that. Instead, you can request any length and be specific, and we can cut it to that length without having to rely on predetermined values that were set based on what we think you may want.

That gives us more flexibility and will hopefully mean that you, the customer, can receive exactly the end product that you wanted, fulfilling your needs.

Additionally, because MX-R Support Frames utilise back-to-back channel, it gives the ability to support heavier-duty AHUs than typically channel systems have been able to before. Intermediate feet can also be positioned wherever needed to enhance loading capabilities.

On top of this, all MX-R components have undergone controlled stress testing, simulated structural analysis and real-world load-bearing testing. This should give you peace of mind about the safety of your workforce and your rooftop equipment, and in turn, help you provide a golden thread of provability/information, ensuring that your plant has been installed accurately.

All in all, the majority of other channel-based roof support systems are not truly modular, therefore making them awkward to install. This can take up unnecessary design and labour time, plus they have generally lower load ratings.

What makes an MX-R Support Frame ‘truly modular’?

All of our products are what we like to call ‘bespoke off-the-shelf’. This means that no matter what AHU/plant you have or its length, you’ll never need to ask for any bespoke, complex, or expensive parts that may come with long lead times.

It will always be predetermined units at differing intervals, and all components are standardised and stocked in-house, ready for next-day delivery.

You can also choose from single or back-to-back channel, and either 350kg or 500kg feet, to make your frame as heavy-duty or as lean as you desire.

How do I configure an MX-R Support Frame?

We appreciate that most customers won’t be previously familiar with this concept, so we’ve created a product data sheet specifically tailoring every single design of MX-R. It should help you understand how to create the correct Support Frame so that it can follow MX and MX-R’s mantra of provability.

In some cases, the Design team can get involved to create custom configurations to override limitations if a safe solution can be reached (e.g. cross rails over 2m long with intermittent feet).

Here are the simplified steps:

- Select from the single or double frame options to suit the dimensions and weight of the equipment.

- Find the overall length of the Side Rails by adding a minimum of 300mm to the length of the unit.

- Find the length of the Cross Rails by adding a minimum of 150mm to the width of the unit.

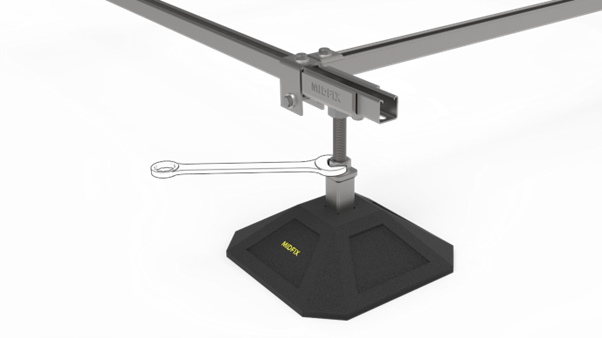

- Select the number of Cross Rail sets needed to build the frame according to the maximum allowable Cross Rail loads and spacings. Sets consist of 2 channel connection brackets and 2 adjustable legs.

- Add the corresponding number of feet. Select from 350mm or 500mm according to the load.

- Check that the foot pressure is within the allowable limits of the roof build-up as detailed by a structural engineer.

- Additional legs and feet can be added in any position on the frame if required. The load will depend on where they are positioned on the frame.

How easy is it to assemble an MX-R Support Frame?

MX-R Frames also come with another booklet including instructions for onsite assembly.

The lack of box section and connections, awkward constraints, and sliding parts makes for a customer-centric design. This ensures that anyone can put together an MX-R Frame with ease and without help, subsequently keeping on-site costs to a minimum.

Instead of sliding parts through box section or channel, we can simply drop our cross rails over the top of our side rails to ensure that your installation goes as smoothly as possible.

Effectively, it means you can have fewer people working and still produce the same task that would conventionally take more people to achieve.

There’s also the added benefit of adaptability. If you need to redistribute weight on the AHU for any unforeseen reason, it’s very simple to do so, even as one person. In addition, the legs are height adjustable to adapt to varying roof pitches, and cross rails can be repositioned if necessary to accommodate any loading challenges that may arise.

What are the limitations of an MX-R Support Frame?

Just like with anything else, there are of course some limitations to MX-R.

Width is certainly one of the main things you should consider to determine whether an MX-R Support Frame is right for you. The maximum width it can accommodate is 2 metres, so if you’ve got a particularly wide AHU/plant (i.e. anything above that) this is not something we currently offer. However, we’ve found that for the vast majority of cases, 2 metres is more than adequate.

The weight distribution must be accurately calculated as well. For a single channel frame, for example, the maximum load that can be applied per cross rail is 500kg based on a maximum rail spacing of 1500mm. (You also have to keep the spacing in mind). For double channel, it’s 1000kg across 2000mm spacing.

Now that’s based on uniformly distributed loads. But if your basic calculations fall outside of these load capabilities, or if there was a point load, you’d have to engage with a design specialist to identify where the loads fall and whether MX-R would be a viable option, and if not, what alternatives you can use instead.

Lastly, roof pitch should also be taken into account. The feet are only adjustable by 100ml, so the size of your frame will limit how much pitch variation you can get out of it. If the frame is longer, you’ll get less pitch because of the distance between the feet, and if it’s narrower, there will be a higher pitch. There’s no maximum degree as such, but just bear in mind that the frame’s dimensions and the feet’s adjustment can limit the roof pitch capability.

Conclusion

We are slowly but surely making strides towards a better future in M&E and MX-R Support Frames is one of those strides.

While there’s nothing fundamentally wrong with the traditional methods of fabricating plant support frames, contractors have had to face increasing project deadline pressures, cost issues, and challenges with on-site assembly. So, they’ve learnt the hard way to start using more efficient, time and cost-saving techniques, and that is why we decided to start optimising – as an answer to that.

With the introduction of MX-R, installation times can be drastically reduced, adjustment is much less onerous, and in most cases, it can even be sourced premade to your specifications.

Do you see yourself switching to modularised plant support frames?