How do you know you’ve picked the most optimal plant support frame for your rooftop projects? What if you’ve been over-engineering; going above and beyond what you need?

What if you can reach a solution that not only does exactly what you need for the application but also saves money and material?

When it comes to rooftop plant support frames, you have a few options. You could either go the very traditional route of welded steel profiles such as PFC and I-beams. You could even choose non-modular channel-based systems.

But if your priority is good value and efficiency over cost-saving, then you might think of going for a modular system. And there are two main kinds: Sikla Framo modular systems and channel-based modular systems like MX-R.

This article focuses on the difference between these two, giving you transparent information about each so that you can decide with ease which one is right for your applications.

- What is Sikla Framo?

- What is MX-R?

- What has influenced modularisation in rooftop plant support frame designs?

- What are the key differences between MX-R and Sikla Framo for rooftop support frames?

- Conclusion

What is Sikla Framo?

Sikla Framo, shortened to siFramo, is a non-welded modular steel support system made of a compact, off-the-shelf readily available range of components, connected with a single type of screw. It can generally be used in many scenarios; constructing supports, bracketry, load-bearing structures, and of course, frames (including rooftop plant support frames).

If you take the concept of a box section and make it modular, Framo is what you’d get. It can support loads that are beyond the capabilities of channel and would traditionally require off-site fabricated steelwork and heavy steel sections. It also has a unique ridged profile which adds to the loading performance.

While often Framo is used for plant support frames for said load performance, people also commonly default to it simply for its modularity and adjustability; which couldn’t be found with traditional systems or channel-based systems. But with the introduction of modular channel-based systems, this has changed! Bringing us to our next point…

What is MX-R?

Non-modular channel-based (or strut) systems have been trusted in the M&E industry for almost a century (you read that right!) and are a go-to product for many contractors. They come with many benefits, including their versatility and ease of configuration which gives them the ability to be made bespoke.

More importantly, they don’t require excessive labour and are relatively cheap. And while Framo is lightweight in comparison to regular box section, channel is even lighter, and is suitable for supporting most plants/units for rooftop applications.

The only problem is that the modularity aspect of Framo was undeniably met with such positive feedback that people began to rely on it for convenience, even when the unit weight didn’t call for that. And that’s where MX-R comes in!

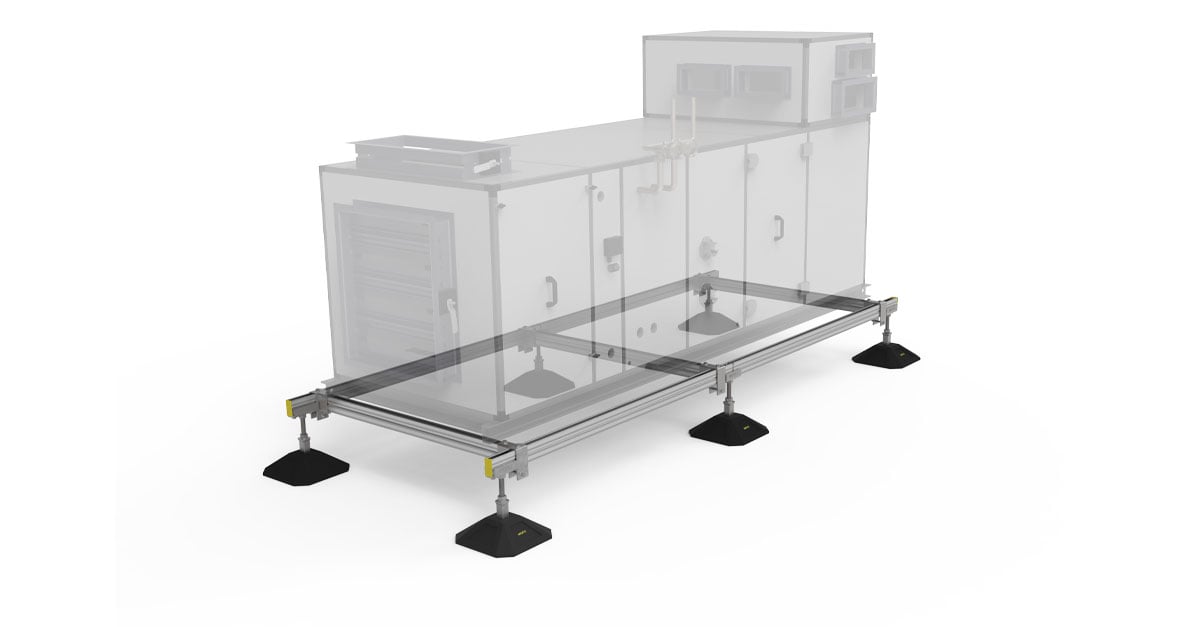

In short, MX-R is a modular and adjustable version of a channel-based system. It utilises traditional ‘legacy’ channel (both single and back-to-back) and provides the aforementioned benefits of Framo, but without the added weight or cost, for use when high load-bearing capacity isn’t needed. As mentioned, Framo can sometimes be overkill when being used to support units that aren’t that heavy. In those instances, MX-R might be the perfect ‘Goldilocks’ solution, if you will.

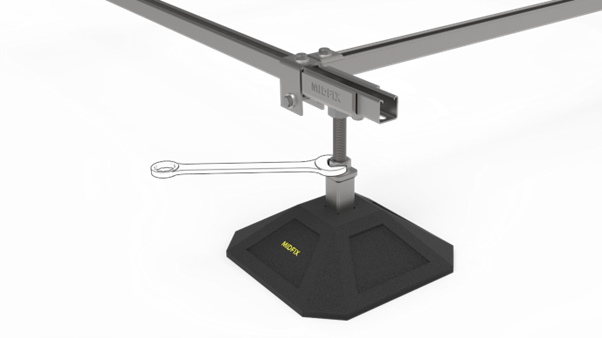

The channel is used in conjunction with fittings/connections between the beam sections and cross members, and feet whose height you can adjust up and down, allowing for that adjustability.

What has influenced modularisation in rooftop plant support frame designs?

While there’s nothing fundamentally wrong with the traditional methods of fabricating plant support frames, contractors have had to face increasing project deadline pressures, cost issues, and challenges with on-site assembly. So, they’ve learnt the hard way to start using more efficient, time and cost-saving techniques, and that pioneered modularisation.

With modular designs, you can adjust very quickly and easily as and when you need. In most cases, you can even source them premade to your specifications, drastically reducing installation times on site. This applies to modular plant support frames for rooftops, as well as other support brackets like pipe supports, etc.

What are the key differences between MX-R and Sikla Framo for rooftop support frames?

Some of these have already been touched upon in the above subheadings. Obviously, the key difference is that the former (MX-R) is made of channel, while the Framo modular system is made of…Framo. Who would’ve guessed?!

We also mentioned that Framo has much higher loading capability than channel. In the majority of cases, back-to-back channel would be sufficient to carry your loads. But in cases where you’re supporting something heavier than the limits of channel is when you should start considering Framo – otherwise, you’d likely be overengineering and overspending.

To add, channel is lighter than Framo. MX-R is designed to be a 1-man job and is easy to install – while Framo is convenient, it is a bit more difficult to erect. That also means Framo would be more time-consuming to assemble.

Because MX-R is only made of channel, it can be more cost-effective than Framo, (though marginally more expensive than regular channel due to its added benefit).

While Framo is adjustable in many ways, its pitfall is that the height of the feet can only be changed by either cutting the leg or replacing it with the correct length leg. On the other hand, MX-R has adjustable feet up to 100mm.

However, Framo only requires FLS screws whereas, because it’s made of traditional channel, MX-R requires more components including set screws, washers, channel nuts, and nuts. (Framo requires many more fixings per frame, though.)

Even still, MX-R is designed with rooftop plants specifically in mind – whereas Framo is more of a generic product, and while it has many uses, isn’t well-adapted for this particular use.

Furthermore, Framo has a distinctive aesthetic and burly look to it, with its many ridges and holes, and MX-R doesn’t have that. Many choose it simply because they find it easier on the eye than channel.

Conclusion

All in all, you can’t really go wrong with either option. Both are likely to do the job more than adequately (as long as you bear in mind the load).

Regardless, the point is that there’s no use in choosing something over-the-top, that would cost you more money and time to assemble (Framo) unless you actually need to.

With regards to plant support frames, in most cases, you don’t need the higher load capabilities of Framo and can get away with back-to-back channel. Now that there is the option to use channel while still keeping the adjustment benefits, why wouldn’t you?